Copper machined parts are crucial components in various industries, from automotive to electronics. The efficient and precise machining of copper parts requires the use of advanced techniques and processes. In this blog, we will explore different methods used for fabricating copper machined parts and the benefits they offer.

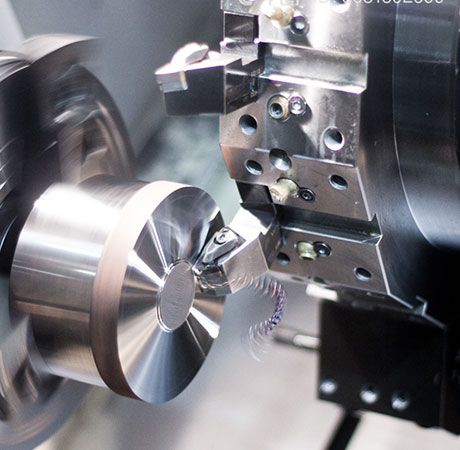

CNC Machining

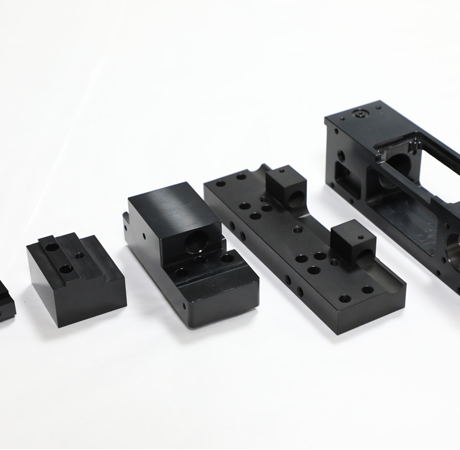

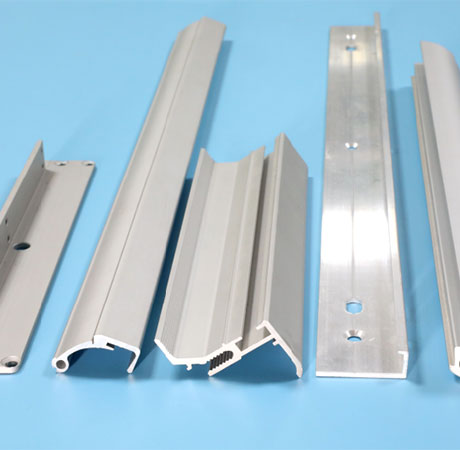

One of the most commonly used techniques for producing copper machined parts is CNC machining. CNC (Computer Numerical Control) machining involves using computer-controlled machines to accurately cut, drill, and shape copper materials according to precise specifications. This method offers high levels of accuracy and repeatability, making it ideal for producing complex copper parts with tight tolerances.

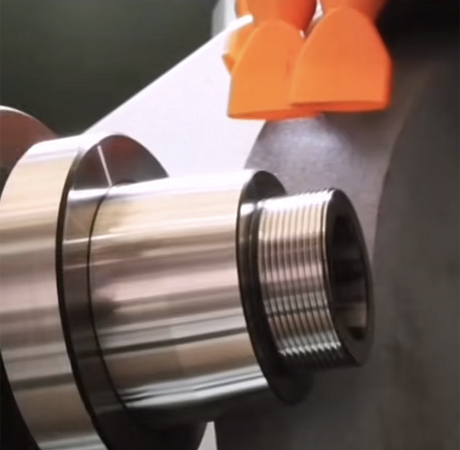

Turning and Milling

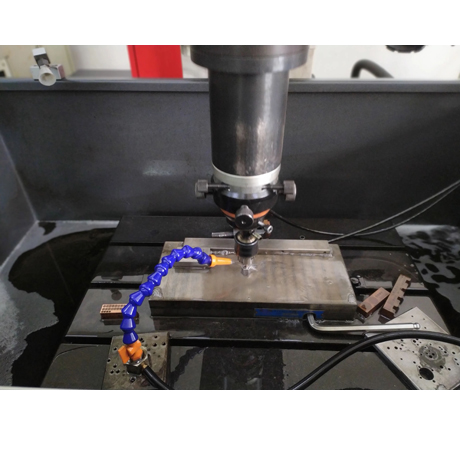

Turning and milling are traditional machining processes that are still widely used for fabricating copper parts. Turning involves rotating a workpiece against a cutting tool to create cylindrical shapes, while milling involves removing material from a workpiece using a rotating cutter. These methods are suitable for producing simple copper parts with basic shapes and features.

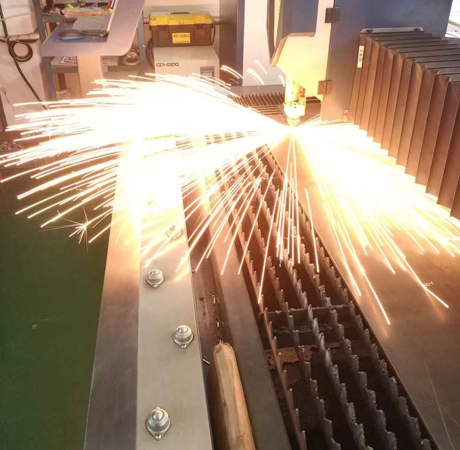

Electrochemical Machining

Electrochemical machining is a non-traditional machining process that uses electrical energy to remove material from a workpiece. In the case of copper machined parts, electrochemical machining can be used to produce intricate and delicate components with high precision. This method offers advantages such as fast material removal rates, complex geometries, and minimal tool wear.

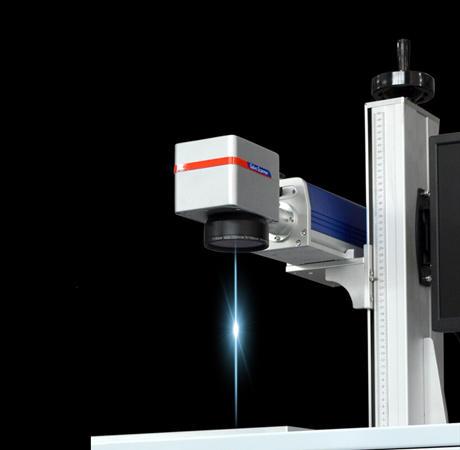

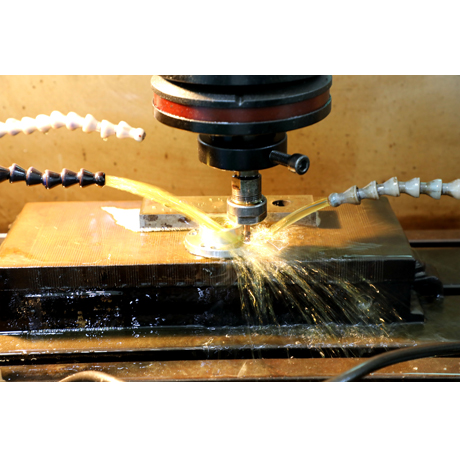

Wire Electrical Discharge Machining (EDM)

Wire EDM is a specialized machining process that uses a thin, electrically conductive wire to cut through copper materials accurately. This method is particularly suitable for producing copper machined parts with intricate shapes and tight tolerances. Wire EDM offers benefits such as high precision, low tool wear, and the ability to cut hardened materials, making it a popular choice for manufacturing copper components.

In conclusion, the fabrication of copper machined parts involves a variety of techniques and processes, each offering its advantages and benefits. CNC machining, turning, milling, electrochemical machining, and wire EDM are just a few of the methods used to produce high-quality copper parts for various applications. By understanding the strengths and limitations of each technique, manufacturers can choose the most suitable method for producing copper machined parts that meet their requirements.

Sibai is a renowned precision cnc machining company known for its expertise in producing high-quality copper machined parts using advanced techniques and processes. With a commitment to precision engineering and superior quality, sibai ensures that its copper parts meet the highest standards of performance and reliability. Whether you require custom copper components for your automotive project or electronic device, sibai has the capabilities to deliver precision machined parts that exceed your expectations. Choose sibai for your copper machining needs and experience the difference in quality and service.