Sibai Provides Many Mechanical Parts For Driving System

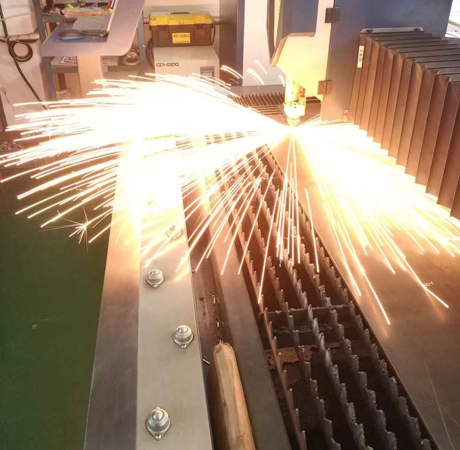

For front and rear-drive cars, the torque from the engine is transmitted to the rear wheels through the clutch, gearbox, universal joint, drive shaft, final reducer, differential, and half shaft in turn, so the rear wheel is also called the rear wheel or drive wheel. When the driving wheel gets torque, it gives a backward force to the ground, and thus causes the ground to generate a forward reaction force against the driving wheel, which is the driving force of the car. The front wheels of a car generally have no direct power connection with the drive train, so they are called driven wheels. The composition and arrangement of the drive train varies with the type of engine, installation location, and application of the vehicle. For example, off-road vehicles mostly use four-wheel drive, and then an assembly such as a transfer case is added to its drive train. For front-wheel drive vehicles, there are no drive shafts and other devices in the drive train.

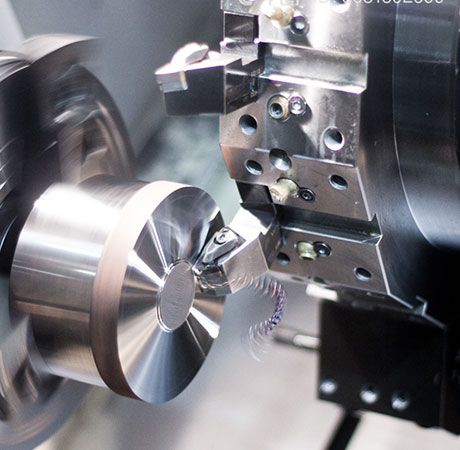

So, it is not easy to provide the driving system parts. The driving system parts are always at the top standard of manufacturing.

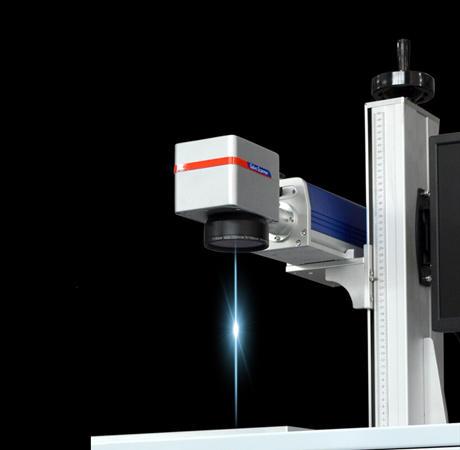

Sibai doesn't provide any whole driving system products. But Sibai did many mechanical parts for driving system. As a European trusted supplier, Sibai provides many kinds of gears and shafts for the driving system parts these years.

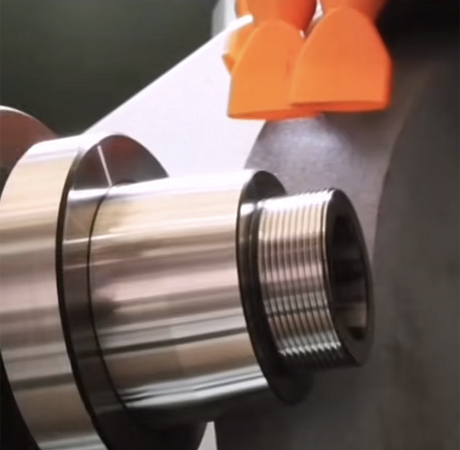

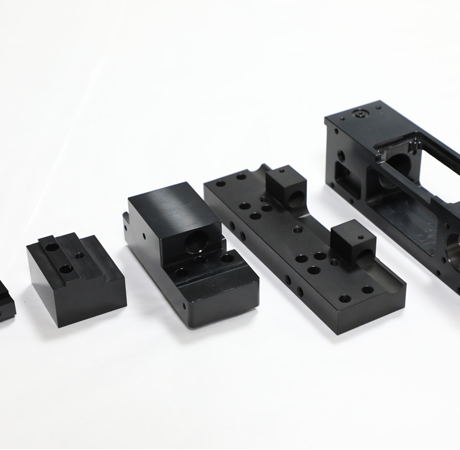

For example, Sibai provide a groupd of gear parts from 16MnCrS5 material. The surface treatment is blacked (brüniert). The dimension is around φ45*58 or φ48*41. It takes a very very long production time on these gears. Because it will take long time to complete the teeth of the gear. And the teeth of the gear will be the key of the good quality of these parts. Sibai can control the quality of these gears very well now.

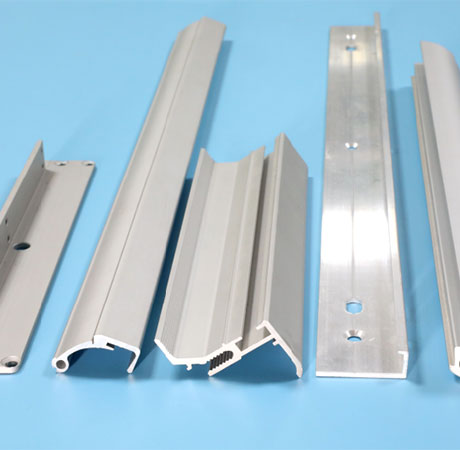

Sibai can also provide many kinds of shafts according to customers. The material of these shaft are 1.4305,1.4301 and C45. The dimension are from φ6*47.5 to φ150*42. Of course, the European customers are very satisfied with these gears and shafts Sibai made. Sibai can deal with the complex and difficult processing of these gears and shafts very well now.

Why Machining Service Matters for the Driving system

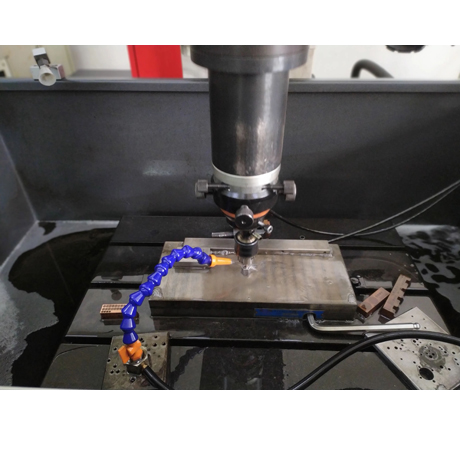

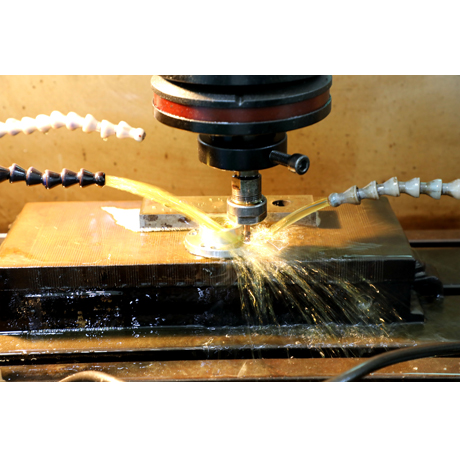

The driving system requires the top standard of manufacturing, and asks for high standard of manufacturing and quality management, strict process flow.

Sibai Driving System Machining Capabilities

Sibai doesn't provide any whole driving system products. But Sibai did many mechanical parts for driving system. As a European trusted supplier, Sibai provides many kinds of gears and shafts for the driving system parts these years.

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.