1. Titanium alloy has the characteristics of low thermal conductivity, serious hardening during process, high affinity with tools, and small deformation, which are the essential reasons for the difficulties of processing Titanium alloys.

Its machinability index is only 20% of that of free-cutting steel. The thermal conductivity of titanium alloy is only about 16% of that of C45 steel. The heat cannot be conducted in time during processing, resulting in local high temperature of the cutting edge, which is easy to cause tool diffusion wear. The hardening of titanium alloy is obvious, which causes certain difficulties forr following processing. What’s more, the workpiece is also easy to get clamping move.

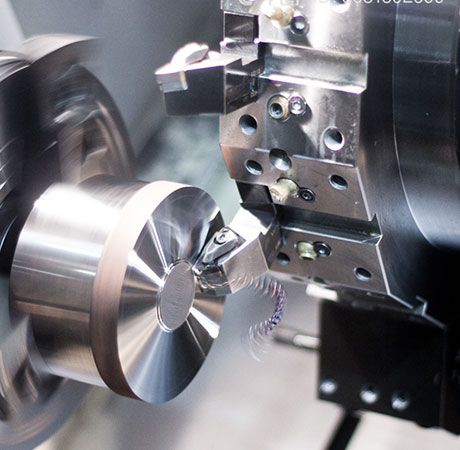

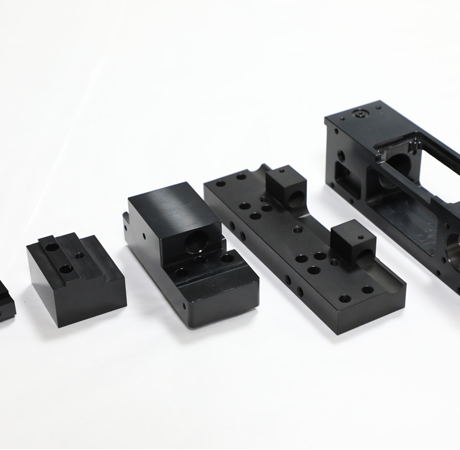

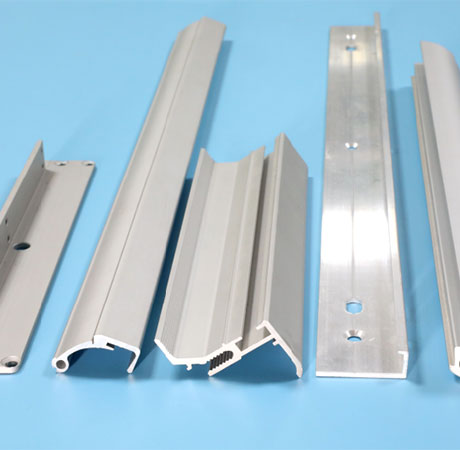

Sibai controls above process difficulties by choosing the appropriate milling cut tools for titanium alloy, which can increase the processing strength and improve the surface finish.

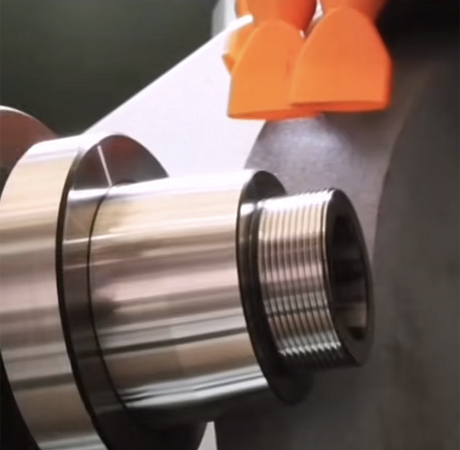

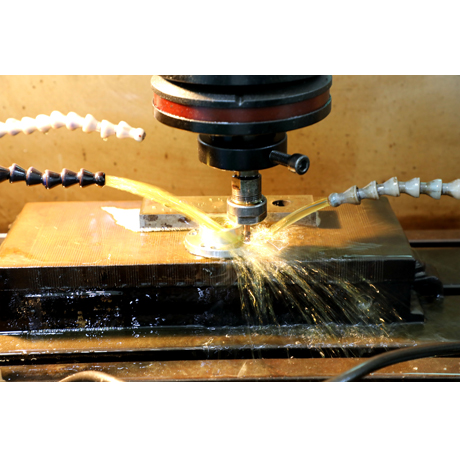

2. To choose a cutting tool that can keep sharp continuously, such as a tungsten-cobalt carbide milling cutter or a ceramic milling cutter is a way to control Titanium alloy machining.

When machining, we should reduce the rake angle of the tool appropriately, and dissipate heat by increasing the contact between the cutting and the rake face. Meanwhile, the relief angle of the tool is increased to reduce the tool bonding caused by the frictional contact with the tool flank when the machined surface springs back. It is best to have a rounded corner transition on the tip, so that the tool has rigidity.

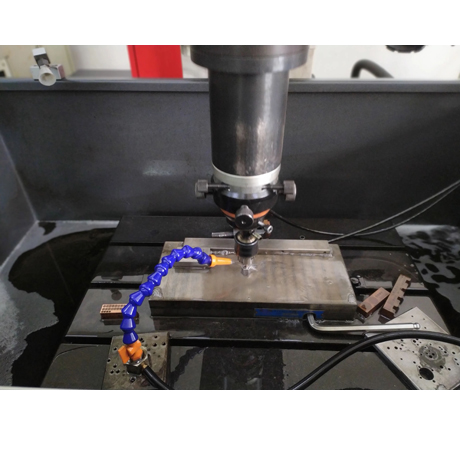

3. In processing, we have to lower the processing speed of the CNC machine. This is also a point for Titanium alloy processing.

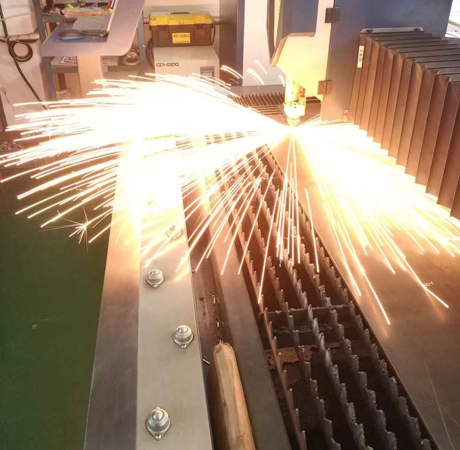

4. During the processing of Titanium alloy, there is a risk of fire. It is very necessary to place a fire extinguisher beside the machine at any time.