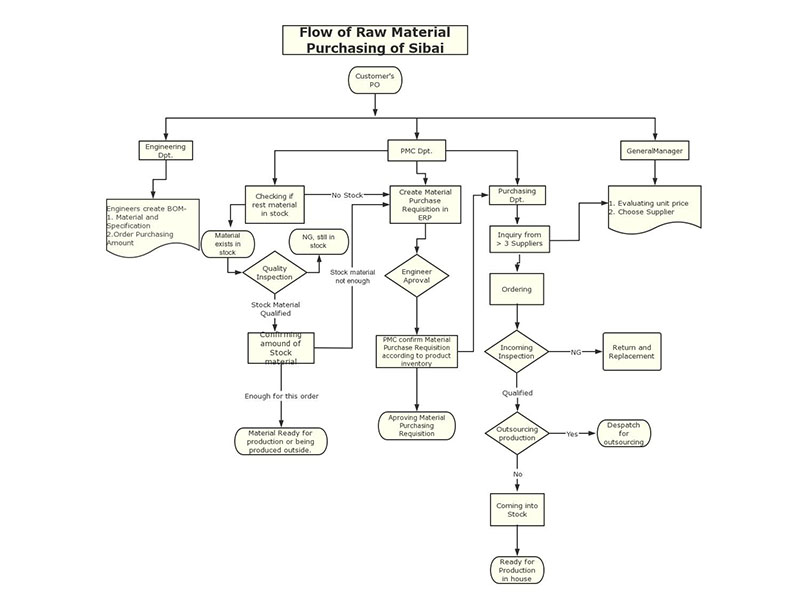

Raw Material Purchasing Procedure

After the order is listed into the system and confirmed, the engineering department first completes the corresponding production BOM in the system, analyzes and determines the required materials/specifications, and volumes, and fills the data into the ERP system.

The PMC department does the following work according to the material specifications and quantities according to the BOM:

The PMC department checks the material warehouse, whether there are available or alternative raw materials, and notify the quality department for inspection and confirmation.

If there are available raw materials, check whether the demand is sufficient for this batch.

If there is no raw material available or not enough for the batch, the PMC department will go to the next step.

The PMC department issues "Material Purchasing Requisition" and passes it to the purchaser. According to the material/specification/volume on the "Material Purchasing Requisition", the purchser inquires from several material suppliers. The quotations are submitted to our boss for decision.

The purchaser places purchase orders and expediting material delivery.

Sibai warehouse department receives the material and notifies the quality department to inspect. If material OK, we accept and put into the warehouse, ready for production or outsourcing. If material NG, we have to return to the material supplier, for replacement.

What should be the attention to raw material procurement?

We should select stable and reliable suppliers for raw material procurement. And we try to choose strong upstream supplier. If you don’t know the source of the supplier's goods and the background of the supplier, it very often leads to failure in actual transactions. The failure of raw material procurement is the basic failure of order operation.

We don't select lowest quotation. We generally ask inquiries to more than 3 suppliers. Generally, we do not choose the lowest price nor the highest price. Instead, we choose a reasonable market price. And we analyze the reasons for the different price quotations.

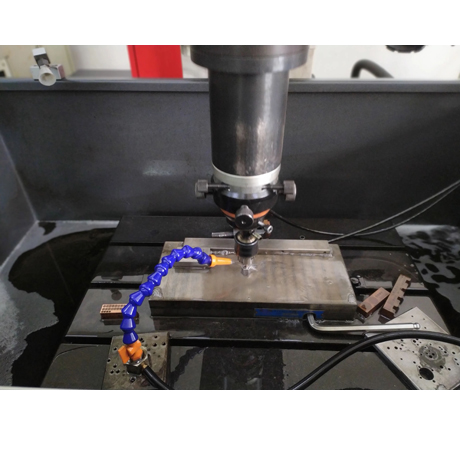

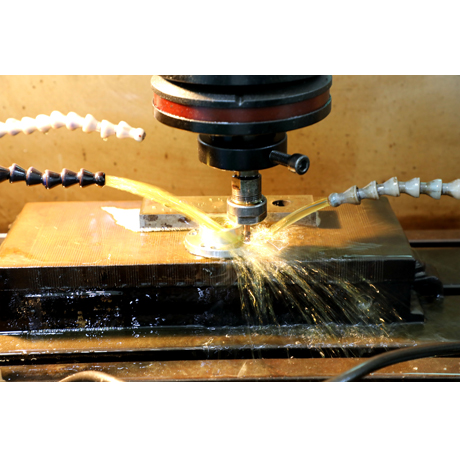

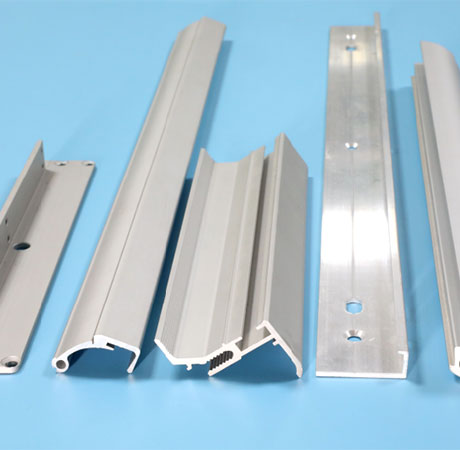

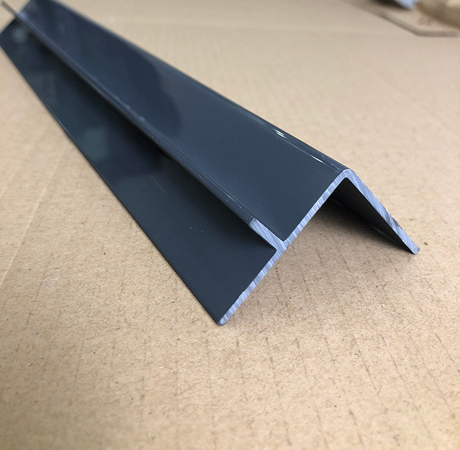

We get a piece of raw materials and inspect it before placing order or before the batch material delivery. We use our own material spectrum analyzer to inspect the material composition to prevent getting unqualified. Besides chemical composition, we should also do a strict inspection on the specifications, that is, the size and tolerance. For the order that requires heat treatment and surface treatment, we will also adopt raw materials to cut into pieces, remove oxide layer or make samples, then do heat treatment and surface treatment to test the treatment effects, whether it can meet the customer's requirements, and then judge whether this batch of materials is qualified.