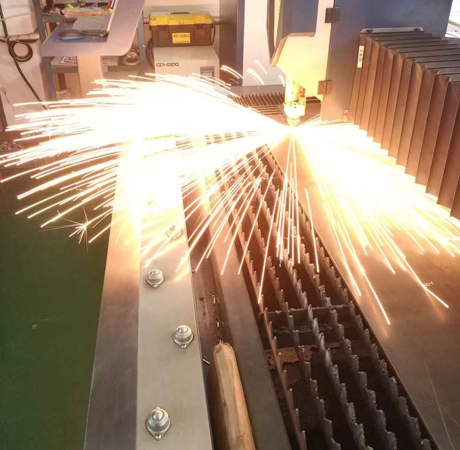

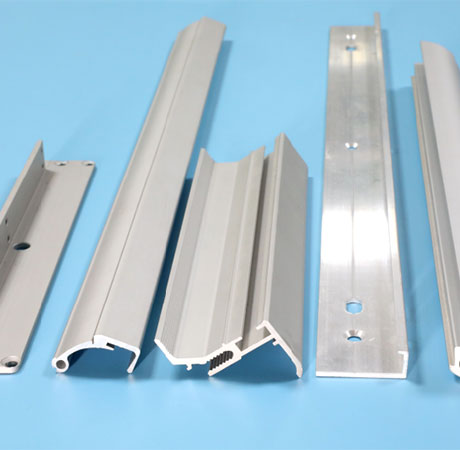

Sandblasting is a very common and important surface finishing process. Sibai often does sandblasting before aluminium anodyzing. Sibai does sandblasting outsourced.

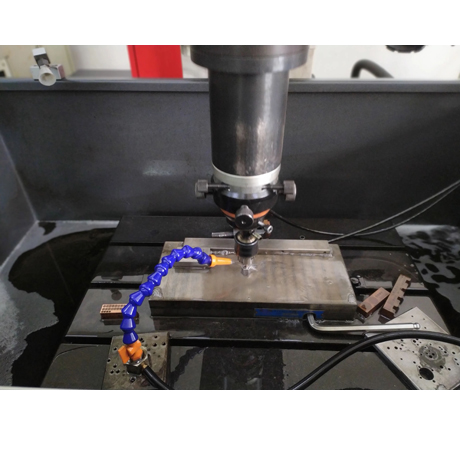

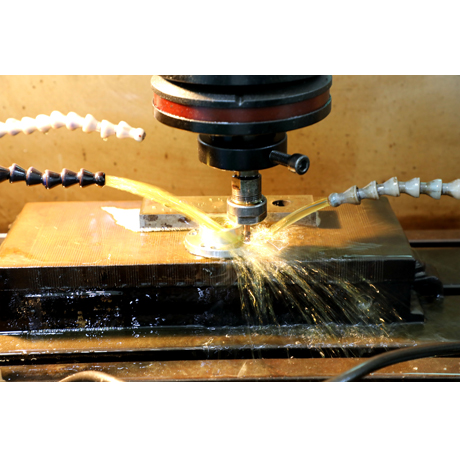

Sandblasting has a wide range of applications. Sandblasting is a pre-treatment process used to treat the surface of workpiece. Sandblasting is a process of cleaning and roughening the surface of the workpiece by using the impact of high-speed sand flow, using compressed air as power to form a high-speed jet beam, and spraying powder to the surface of the workpiece. Due to the high-speed jetting and cutting action of the sand flow, certain dirt removal and different roughness will be carried out on the workpiece, so that the surface of the workpiece can obtain a certain degree of cleanliness and different roughness, so that the mechanical properties of the workpiece surface are improved. It increases the resistance of the workpiece and increases the adhesion between the surface and the coating. The durability of the coating film is prolonged, and the workpiece is beautified.

For castings or heat-treated workpieces, sandblasting can remove oil and oxide scale on the surface, improve the surface finish, expose the original metal color of the workpiece, and thus improve the fatigue resistance of the workpieces.

The abrasive particles used in sandblasting can be steel grit, alumina, quartz sand, silicon carbide, glass beads, etc. According to the surface state of the part material and the processing requirements, abrasive particles of different substances and different diameters of the abrasives can be selected.