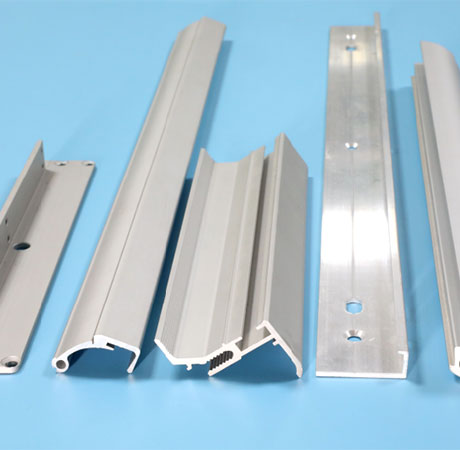

Sibai has abundant aluminum raw material supplier resources in the market, so most of the aluminum material grades can be provided, and the raw materials meet the corresponding standards and certifications.

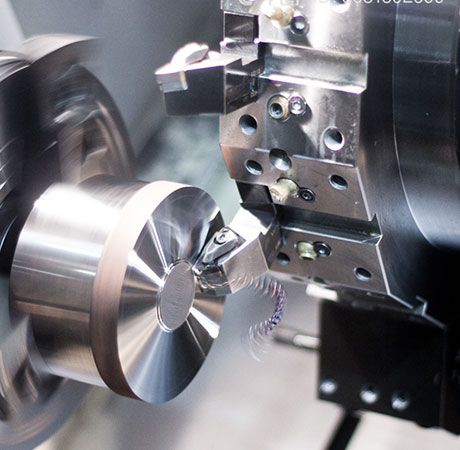

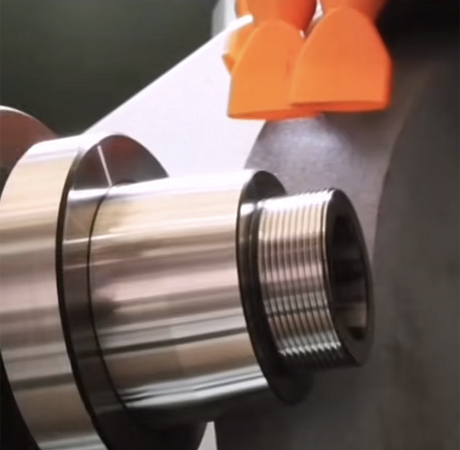

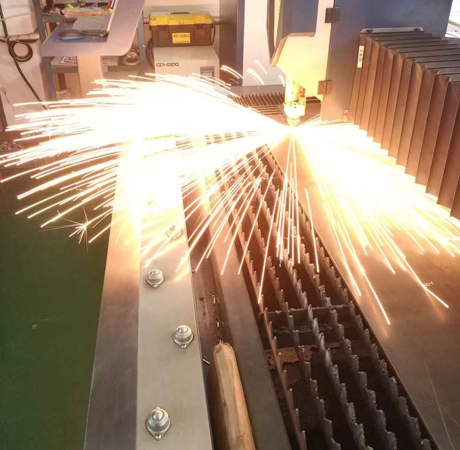

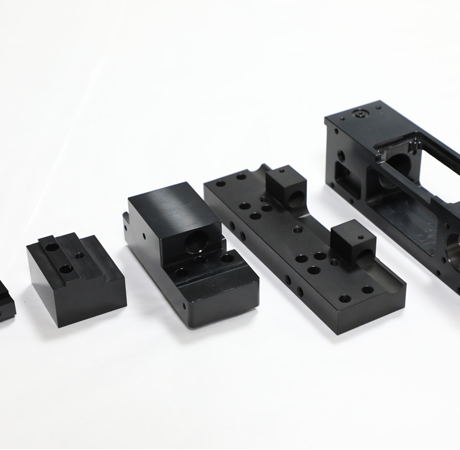

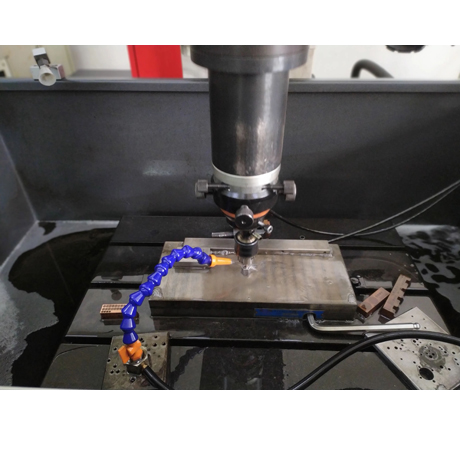

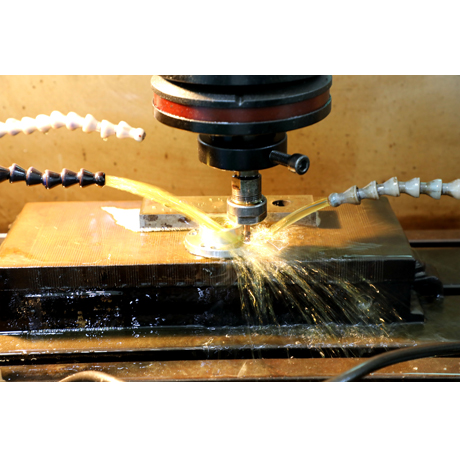

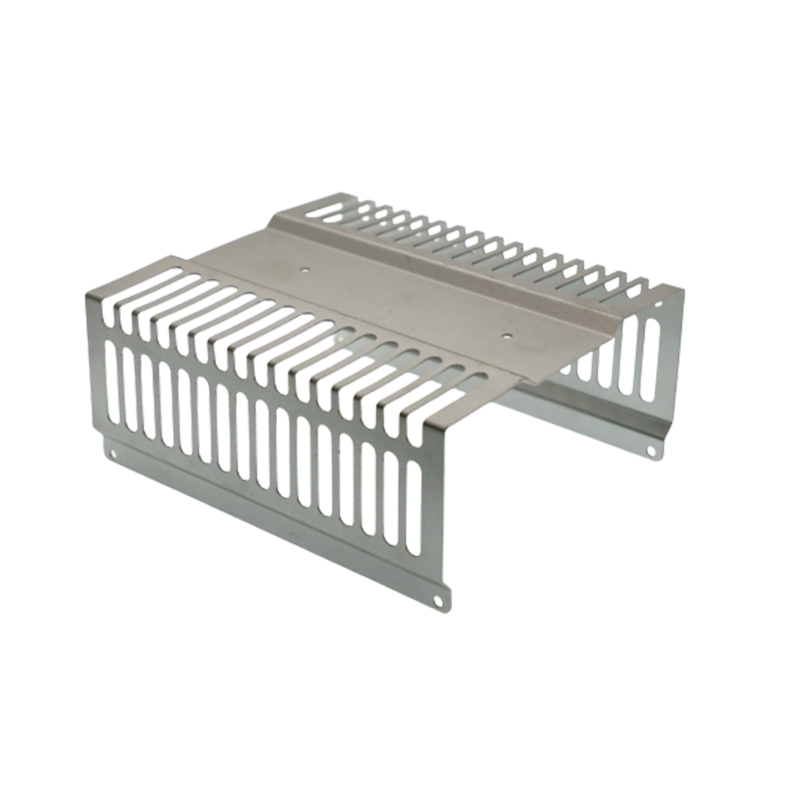

With 20 years of processing experience, Sibai is very skilled and professional in aluminum alloy machining, and the quality, delivery time and service can be guaranteed.

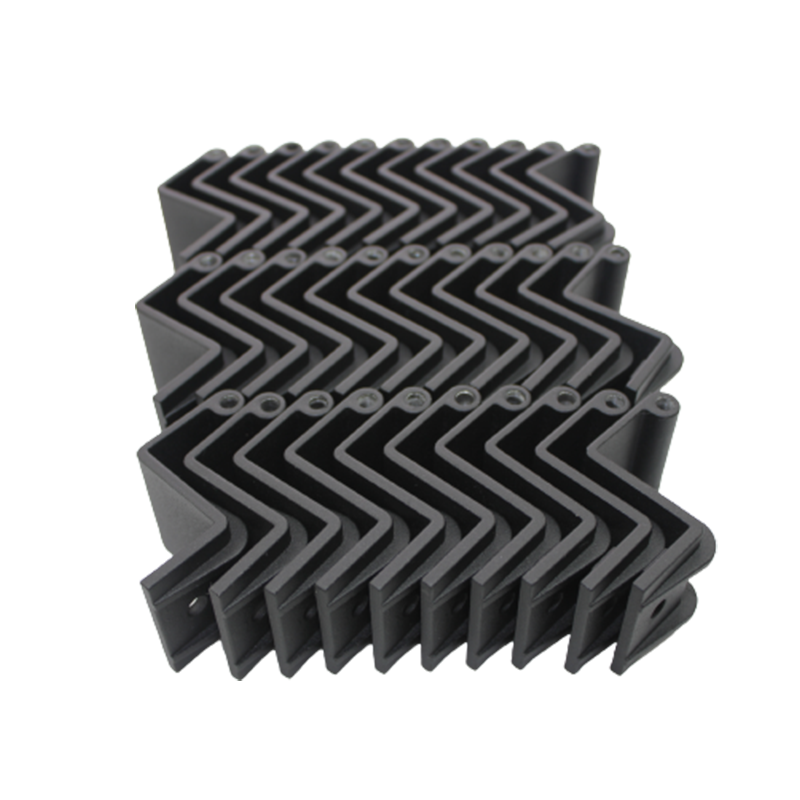

Sibai has countless successful cases of aluminum alloy machining, and can provide customers with design and improvement suggestions to make parts more in line with customer needs.

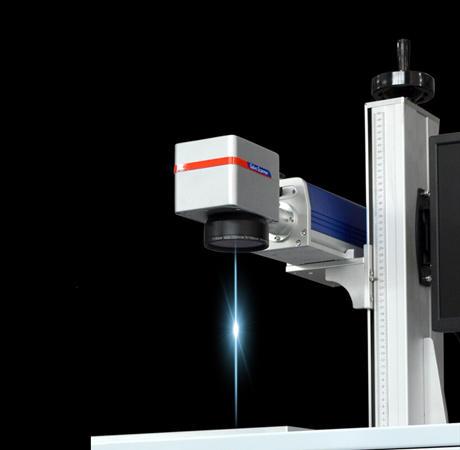

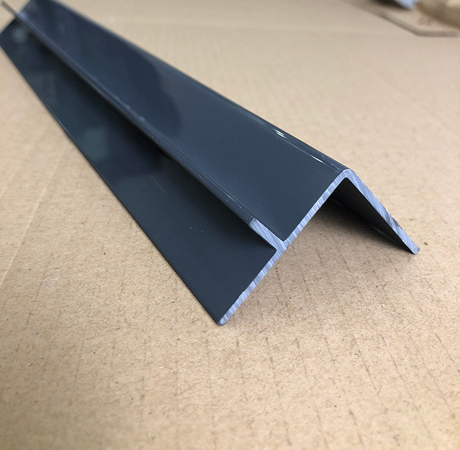

Sibai can also provide various surface treatments for aluminum alloy parts: sand blasting, shot blasting, polishing, chromate, anodizing and powder coating in various colors, etc.