>

There are many stainless steel suppliers in the Chinese market. Some are manufacturers, some are distributors, and some are retail stores. Quality and service capabilities are quite different among them. Therefore, the purchase of stainless steel needs to be very cautious.

When purchasing stainless steel, we must consider the following aspects to avoid purchasing failure. The failure of raw material procurement is not only a failure of raw material itself, but also a failure of machining, a failure of logistics and shipping, a failure of customer imports, a failure of usage and function performance. Therefore, raw material procurement is a source of order success.

In the past 20 years, Sibai has continuously summed up the experience of raw material procurement. Now we summarize the following aspects on stainless steel procurement.

1.Clarifying requests.

When requesting from suppliers, we must get clear the requests, and describe the requirements in details. The requests including grades, specifications, tolerances, specific uses, precautions, and material certificates, we must describe exactly.

2.Selecting big-brand manufacturers.

For large-scale purchases, we are sure to choose big-brand manufacturers. Large manufacturers are important factors to avoid risks. If you choose low prices when purchasing, it is easy to have problems in quality. The big brand manufacturers are more reliable in terms of quality and reputation.

3.Attention to the chemical composition and physical properties of the material.

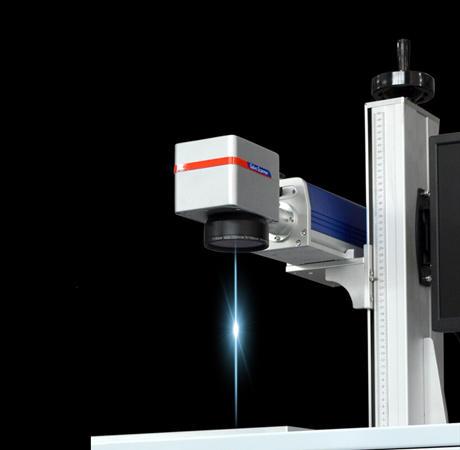

When purchasing materials, we must ask the supplier to provide material certificates. We pay much attention to the details on the certificates, such as production date and furnace number, etc. When we purchases large quantities, we require suppliers to provide a small piece sample before delivery, and use our spectrum analyzer to inspect the chemical composition of the samples. For example, 304 stainless steel, we need to focus on whether its chromium and nickel compositions meet the 304 standard. The lower than standard on chemical composition will affect the customer's later using function.

4.Attention to the specifications and their tolerances.

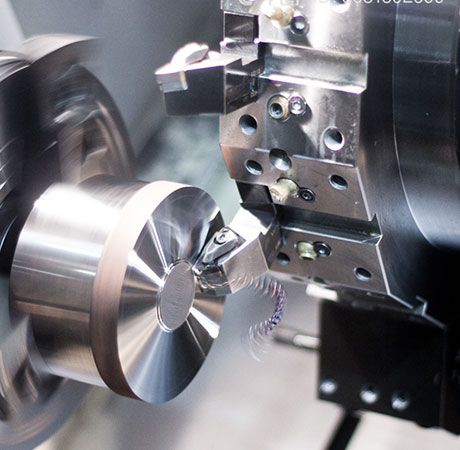

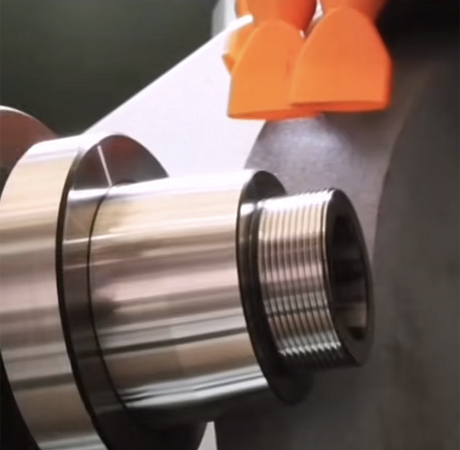

Before purchasing raw materials, we must clarify the specifications of the materials. Sufficient allowance should be left for processing. For example, if you buy a bar or tube of a certain outer diameter, you must give the supplier a clear tolerance range. Because if the tolerance range is not clear, it is likely to find that the machining allowance is insufficient after receiving it, which will affect the machining process.

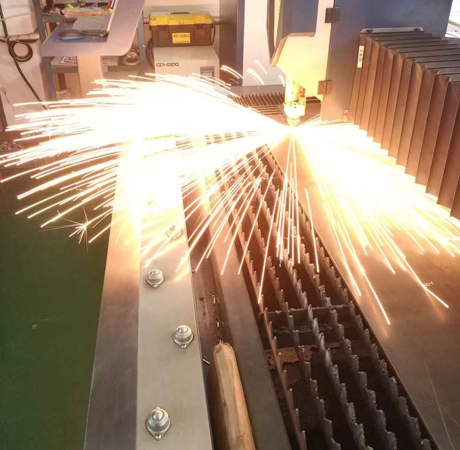

5. When purchasing, it is also necessary to describe the use and processing method of the purchased stainless steel to the supplier. This will help suppliers understand the processing technology and application condition of stainless steel raw materials. Sometimes suppliers will also give reasonable advice to avoid the risks by our own lack of consideration.

6. After the materials are delivered to the warehouse, we must strictly inspect according to the requirements specified in the order. The strict inspections from quality, specification, weight, price and other aspects are necessary to ensure correct incoming materials.

Sibai has accumulated a large number of quality sured and long-term cooperated stainless steel suppliers in the Chinese market. So we can control the risk of purchasing stainless steel and purchase at the most reasonable prices.