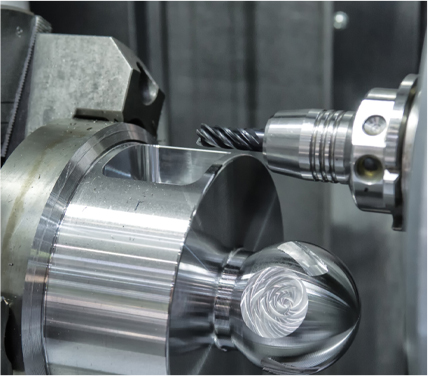

Features of Sibai Machining Capabilities in Fastening

A large number of Chinese fastener products are exported to all countries in the world, and fastener products from all over the world are also pouring into the Chinese market. Fasteners, as one of the products with the largest import and export volume in China, are in line with international standards. Fasteners generally include the following 12 types of parts: bolts, studs, screws, nuts, self-tapping screws, wood screws, washers, retaining rings, pins, rivets, assemblies and connecting pairs, and welding studs.

The most important link in the development and design of fasteners is quality control. There are several key points from raw materials to shipments. In our SIBAI company, there are different inspection methods for these key points. First of all, the raw material inspection includes appearance, size, elements, performance, detection of harmful substances, etc.. The process is about appearance, size, percussion test, forging flow line. Heat treatment is about appearance, hardness, torque, tension, metallography, etc.. The surface treatment is about some hydrogen embrittlement tests, coatings, salt spray, etc., including a detection of harmful substances in shipments. In size and appearance inspection, the common ones are 2D measurement inspection machine, contour measuring instrument, three-coordinate measuring instrument, and image sorting machine. In mechanical and chemical inspection, there are mainly hardness machines (Rockwell and Vickers), tensile machines, metallographic Microscope. In material testing, there is a spectrum analyzer and a salt spray tester.

SIBAI doesn't focus on producing fasteners. But if customers have request, we can help purchase from Chinese professional fastener suppliers.

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.