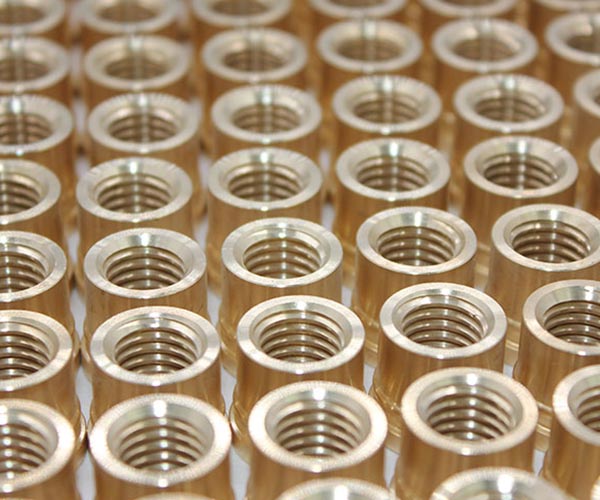

1. Sibai purchases brass bar material from right material supplier, which ensures the good quality of brass material. The common brass material can be MS58, CuZn39Pb3, CuZn37 (CW508L), CuZn30,HPb59-1. H62. We ask material certificate for every batch of brass purchasing.

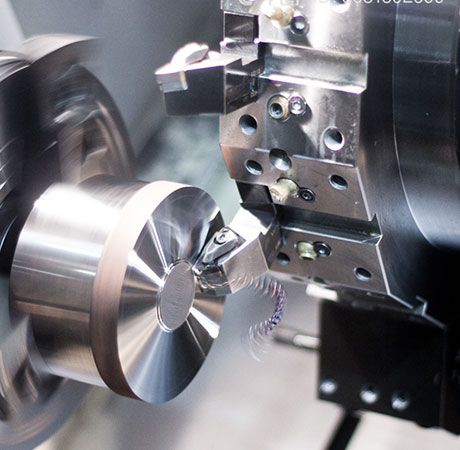

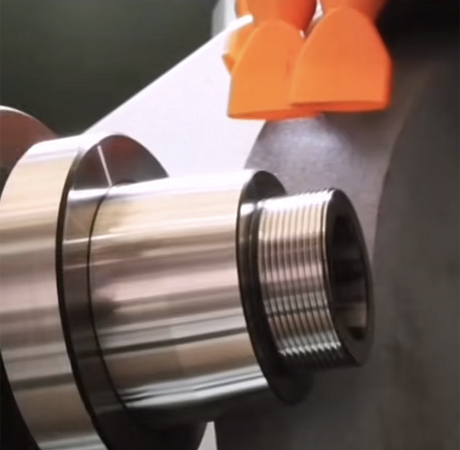

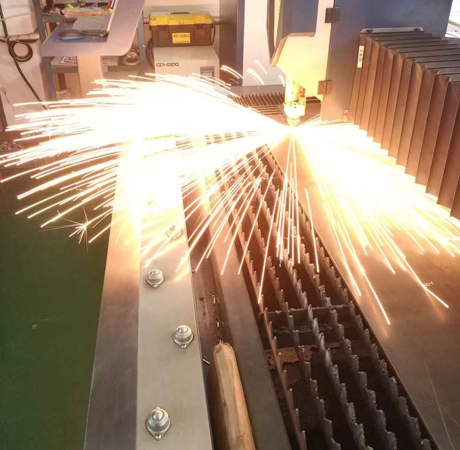

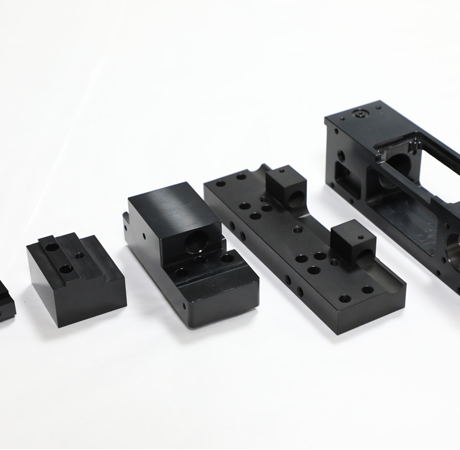

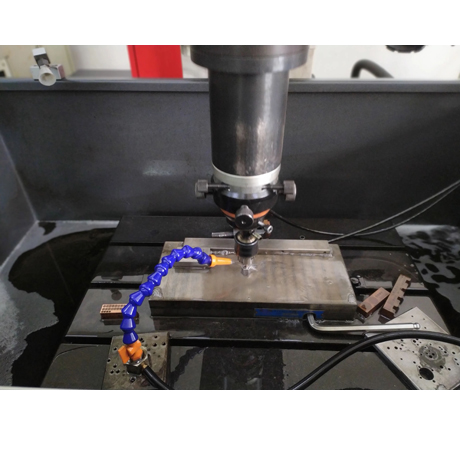

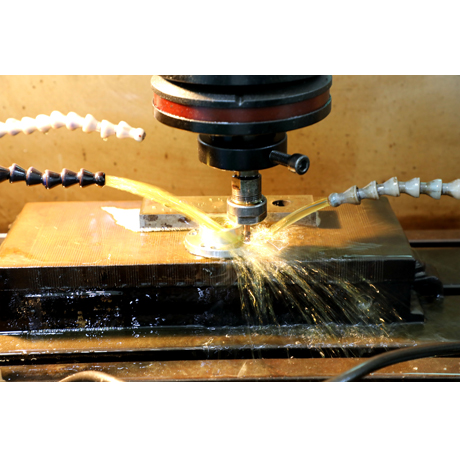

2. Sibai has STAR CNC Swiss type Automatic lathe, CNC turn-mill, CNC 46 Lathes for brass bar machining. The machining is fast speed and accurate. Sibai has also CNC machiningcenter for brass plate material machining. Sibai has 3D coordinate measuring machines, and 2.5D measuring machines, to ensure the machining accuracy.

3. Sibai does every detailed work carefully. After machining, we make ultrasonic, and drying. And Sibai does packing carefully to avoid any damage from collision.

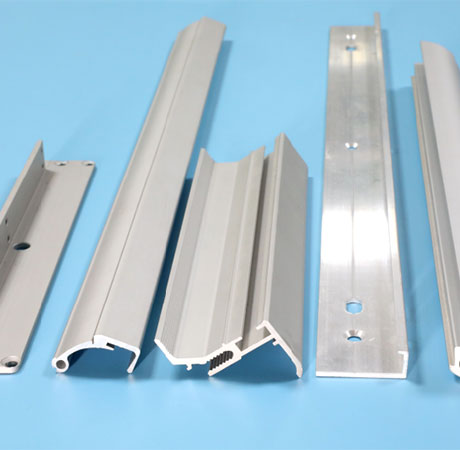

4. After machining, the brass parts are very commonly nickel plated or chrome plated to get perfect surface. The chrome plated brass parts show the gloss like polished stainless steel.