Specification of SIBAI CNC Machining Lock Parts

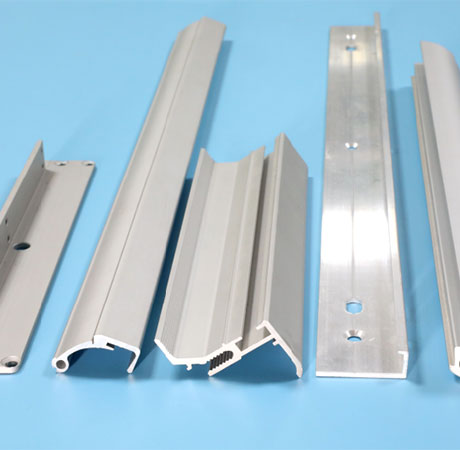

Materials for CNC Lock Parts: copper, stainless steel, zinc alloy, aluminum alloy, etc.

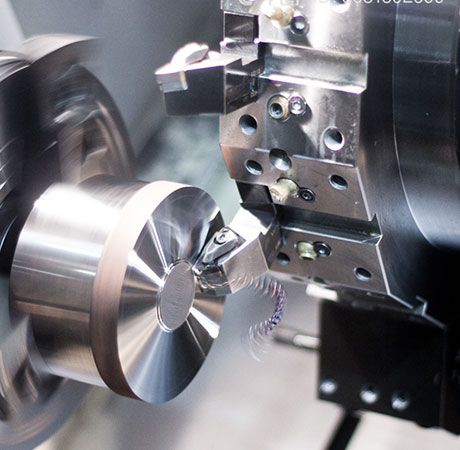

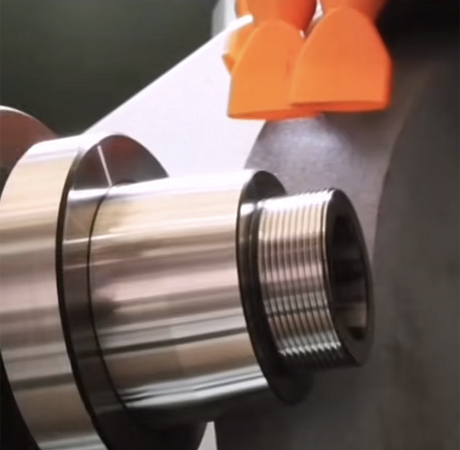

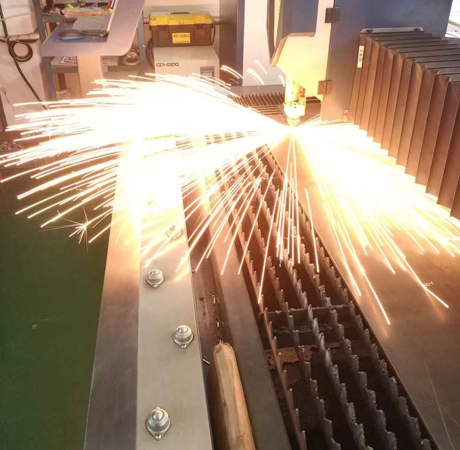

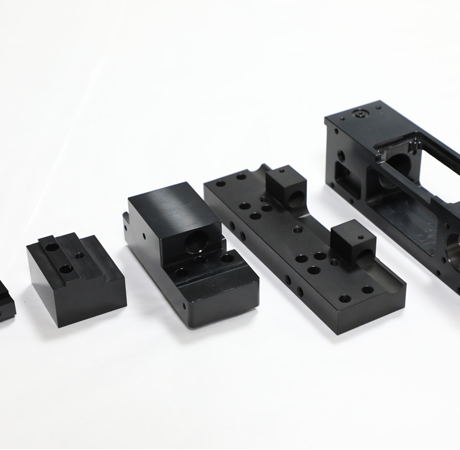

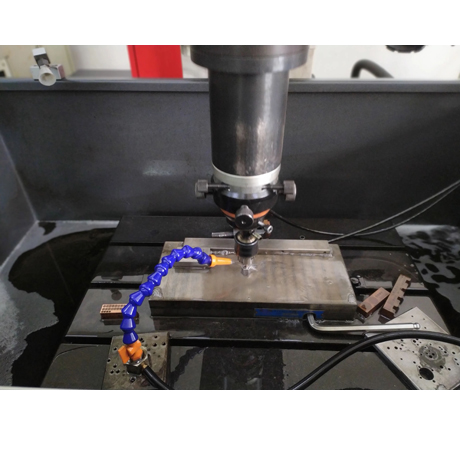

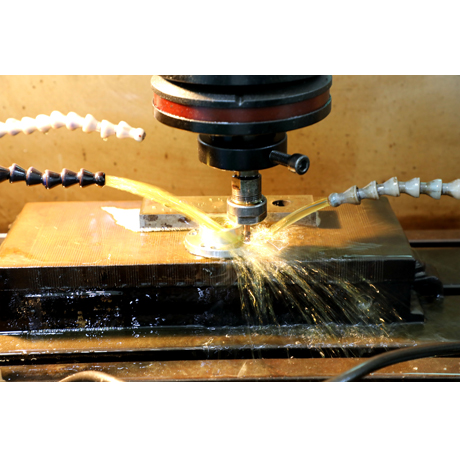

Lock Cylinder Production Process: CNC machining, CNC milling, CNC turning, CNC drilling, etc.

Lock Core and Accessories Applications: cam lock, door lock, push lock, SFIC lock, padlock, IC core lock, security lock, and other types of locks in various industries.

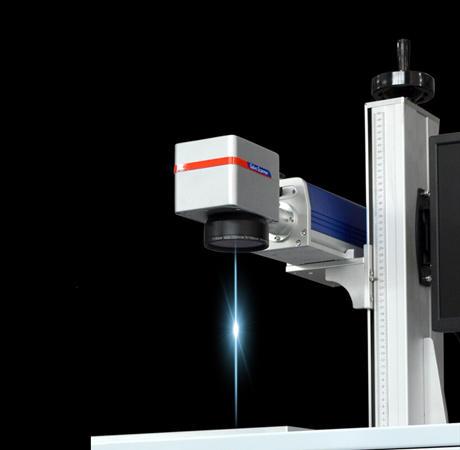

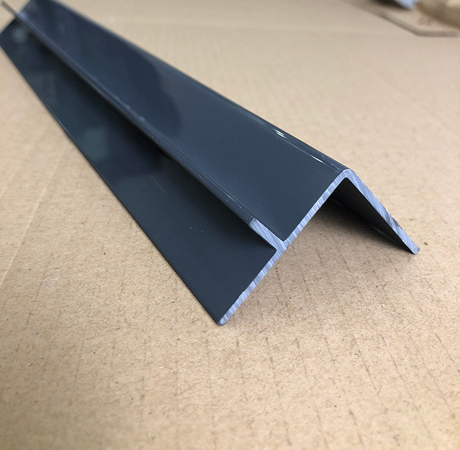

Lock Parts Surface Finishes: Matte Black, polishing, Chrome plating, Nickel plating, Glass bead blasting, etc.

Advantages of SIBAI Lock Parts Machining

Quality assurance: A series of advanced facilities such as salt spray test, spectrometer, with seasoned operators are ready to carry out visual quality standards for our finishing services to avoid the different appearances of the different batch, and more measuring equipment used to confirm the product dimensions.

Cost-effective production: As an ISO certificated manufacturer, Sibai carry out strict control of product quality and production process, maintain high efficiency of mass production, reduce the errors and cost, provide the utmost security at the same time.

Extensive applications: our lock core parts are widely used in electronics, defense, communications, medical, marine and more industries. A large amount of CNC lock products Sibai made have been exported to the United States and majority of European countries.

With the development of security industry in modern society, CNC machining has become the main manufacturing solution of a variety range of locks and keys. To ensure the safety and security of people, the quality of each part on the lock is key important. As the essential device on security doors, home door, market entrance and other places, the demand for locks and lock parts is huge every year.

CNC manufacturing is one of the most efficient and cost-effective production method for large-batch engineering parts in same size. Based on nearly 20 years of experiences on the development and machining of lock cylinder, lock core, and different lock parts, SIBAI is capable to produce customized lock cylinder parts with various customized designs.

If you are looking for a top quality commercial lock cylinder or home lock parts for your project, welcome to contact us through our email.

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.