Quality is built in the process. A good process control is more important than the inspection after processing. Inspection alone cannot guarantee a quality. Therefore, attention to the quality management in the production process leads to a good result. If a plant neglects the prior control of the quality and the processing control, but put importance on the inspection and control after processing, is not a good idea, and will go to failure.

Sibai strictly controls product quality throughout the production process:

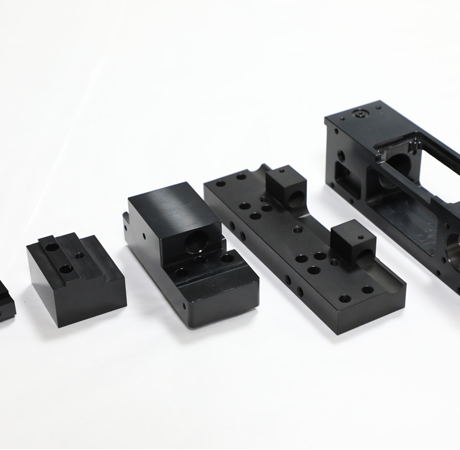

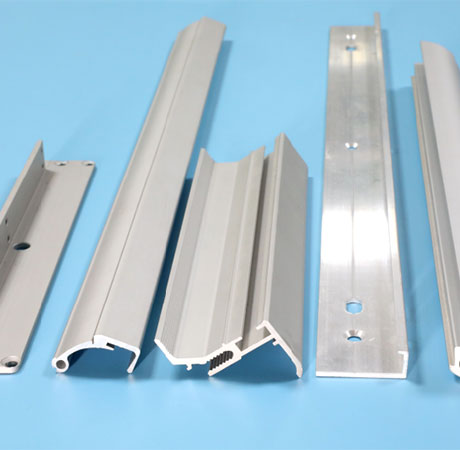

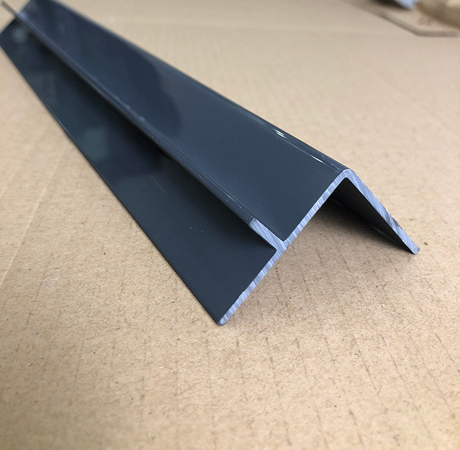

1. In the production process, Sibai production staff will check the type, number and requirements of materials and tools, and clearly mark the materials in the process to ensure the traceability of the material identification and inspection status.

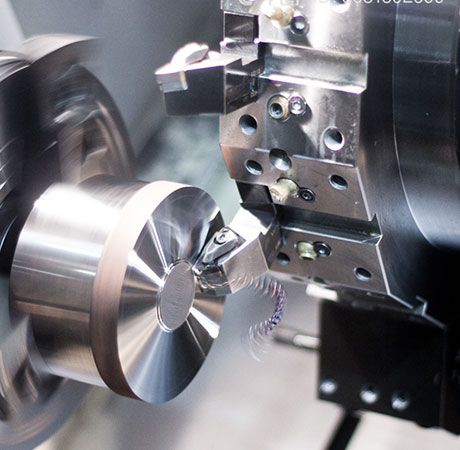

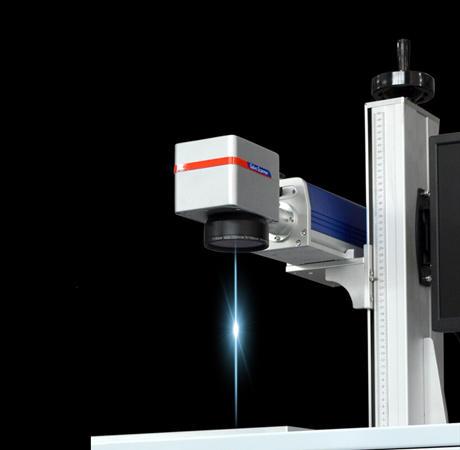

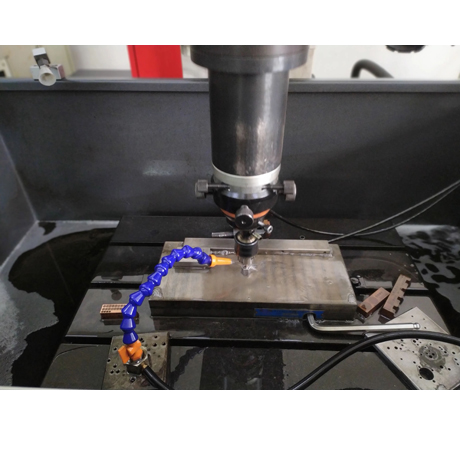

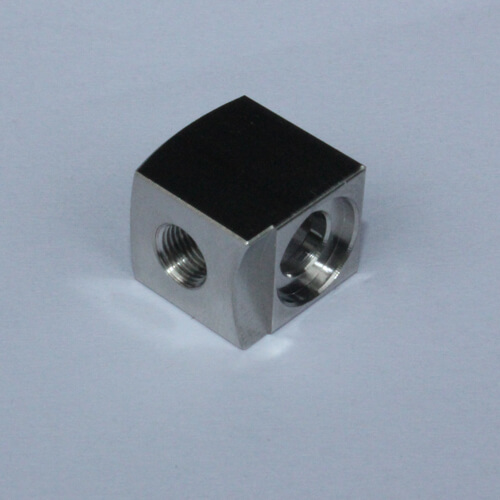

2. Equipment is well controlled and maintained before production and inspection. Sibai makes corresponding regulations for equipment and testing instruments that affect product quality characteristics to ensure their accuracy before production. Sibai makes regular verification and calibration, and a preventive maintenance plan to ensure the accuracy and capability of the equipment.

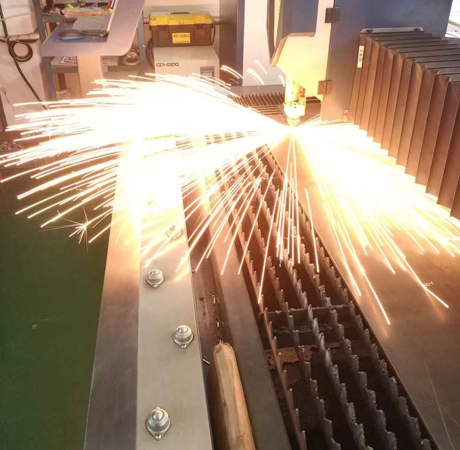

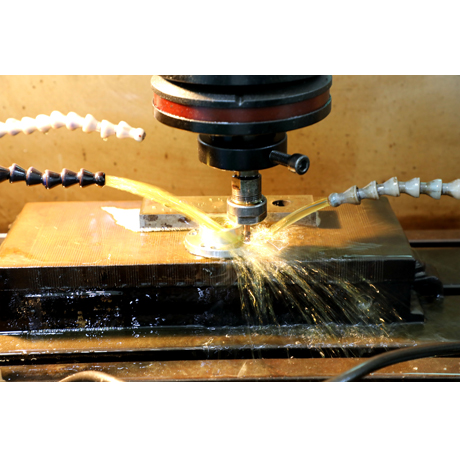

3. For the specific product characteristics that are not easy to measure, sibai’s production staff take special skills and special processes for equipment maintenance and operation, and timely avoid the deficiencies in the process. The staff monitor process parameters and verify at appropriate frequency to ensure that all equipment and operators meet product quality requirements. If it fails to meet the requirements, it should be adjusted from the five aspects: man, machine, material, method and environment, so that the products are produced meeting customers’ requirement.

4. Sibai adopts appropriate methods to identify the inspection status of the process, and through identification to distinguish the uninspected, the qualified or the unqualified products. The responsibility for identification and verification can be traced back through identification.

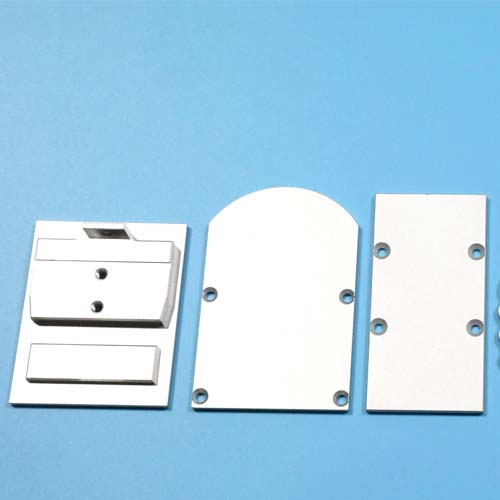

5. According to the established unqualified control procedures, Sibai workers clear mark the unqualified products, and store the unqualified in isolation, and implement the unqualified control procedures strictly and to prevent the unqualified products are delivered to customers.

Sibai Production process quality inspection procedures:

1. Control on raw materials: The on-duty routine inspection reconfirms the raw materials that are about to be put on the machine. The qualified ones can be put on the machine for production, and the unqualified shall be reported as required.

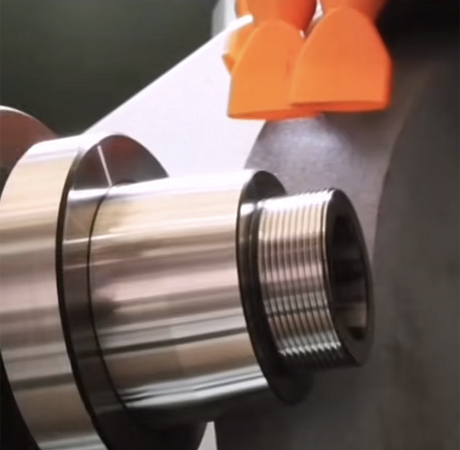

2. First-piece inspection: Before mass production, the responsible inspector strictly inspects the first-piece product according to the engineering drawings to confirm qualification. Only qualified products can be mass-produced. Workshop inspection person must fill in the "First Piece Inspection Report" as required.

3. Process inspection: During the production process, managers and on-duty inspections should regularly conduct random inspections in production, and appropriately increase the frequency of random inspections on the workpieces produced by novice employees, key equipment, or key positions. Products in normal production shall be inspected at a frequency of not less than 2H/time, and the "Process Inspection Report" shall be filled in as required.

4. Last piece inspection: Sibai does the inspecton on the last workpiece to ensure that the whole production process meet the requirements. After passing the inspection, the responsible personnel fill in the "Last Piece Inspection Report".

5. Rework processing of unqualified products: Rework after the end of mass production. Our people inspect the size, performance and appearance of the reworked products, and carry out full inspection if necessary. Those that meet the drawing requirements can be released. For products that do not meet the requirements and cannot be reworked, we fill out a "Scrap Application Form" , indicating the reason for the scrap, and hand it over to the superior for handling off.

Sibai always focus on process control.

Without a good process, it is difficult to have good results. Operators and tuning masters are required to perform self-inspection and mutual inspection, and quality personnel specialize in inspection. Before the product is put on the machine, they should communicate with the quality management personnel, so that everyone has a clear goal and a clear responsibility. For the use of new technologies, new processes and new materials, we train the related personnel in advance to clarify the key points and quality requirements.

Whether it is quality inspection or production, everyone in Sibai has the responsibility to improve quality management. It is a common goal for Sibai's staff, to reducing problems and improving product quality . We firmly believe that "prevention is more important than cure", and it is better to prevent an event before it happens than to cure a disorder after happened. All staff participation Sibai adopts to achieve quality stability and measurablity, Then any abnormality can be found in time and effectively solved.