Carbon steel has become the main material for machined parts in many industries due to its unique mechanical properties, such as tensile strength, yield strength, fatigue strength, impact resistance and required heat treatment properties.

Carbon steels with different carbon contents have different cutting characteristics.

1. Cutting characteristics of low carbon steel

Low carbon steel has more ferrite, good formability and toughness, and the cutting heat generated during cutting is large, which is easy to stick to the knife, and the chips are not easy to break, which affects the surface roughness, so the cutting performance is not good.

2. Cutting characteristics of medium carbon steel

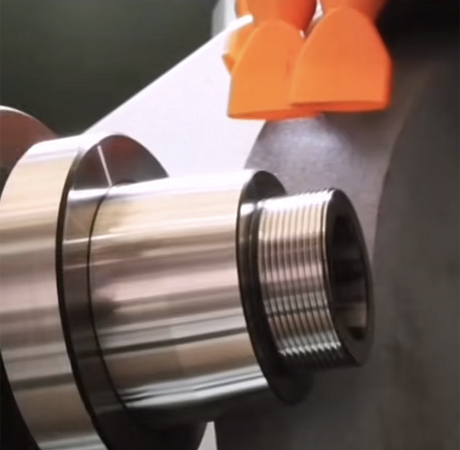

During the turning of medium carbon steel, discontinuous chips will be generated, and the surface quality of the workpiece is better than that of low carbon steel, but the cutting force and tool wear will increase with the increase of carbon content and hardness. Therefore, when the hardness of the workpiece increases, the cutting speed should be reduced. Generally, when the hardness of steel is approximately 240HB, the machinability is better.

3. Cutting characteristics of high carbon steel

During the turning of high carbon steel, the cutting force and tool wear are larger than when turning medium carbon steel due to the higher carbon content. Therefore, lower cutting speeds should be used to reduce tool wear. If the carbon content of the material is high and the hardness increases, the cutting speed should be appropriately reduced during the machining process.

4. Cutting characteristics of free-cutting steel

Since some micro-holes and micro-cracks will be formed during the chip forming process, and these micro-defects will diffuse into the excision layer of the workpiece. After increasing the phosphorus content, phosphorus dissolved in iron can promote chip breaking, which is beneficial to avoid the formation of long tendril-shaped chips. A better surface finish can be obtained for turning free-cutting steel.