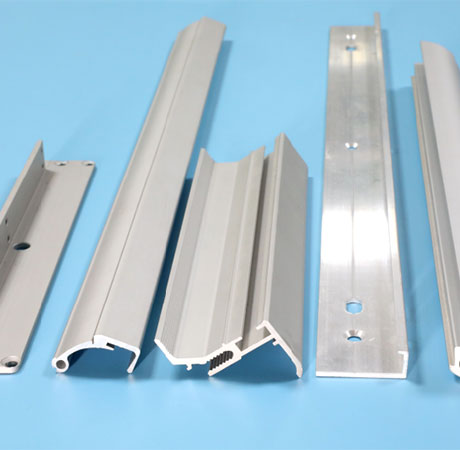

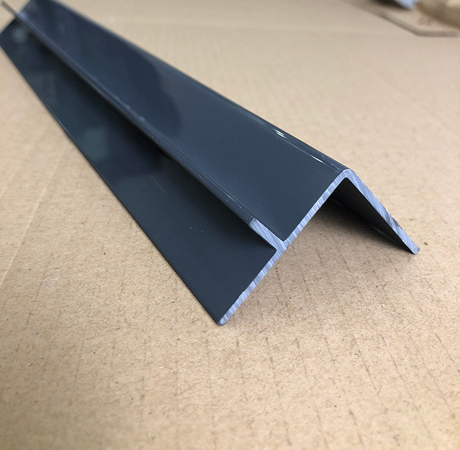

Galvanization is the most common surface treatment in Sibai.

In Sibai, majority of steel products require zinc plating, such as S355 JR, DC01 St 52, etc to be zinc plating blue passivated.

The zinc plating may follow the standard of DIN 50979, and DIN 50961, environmental-friendly without CrVI. For example, DIN50979-Fe//ZnNi8//Cn//T0.

Many brass products require nickel plating. Some copper products, customers require to plate with gold color.

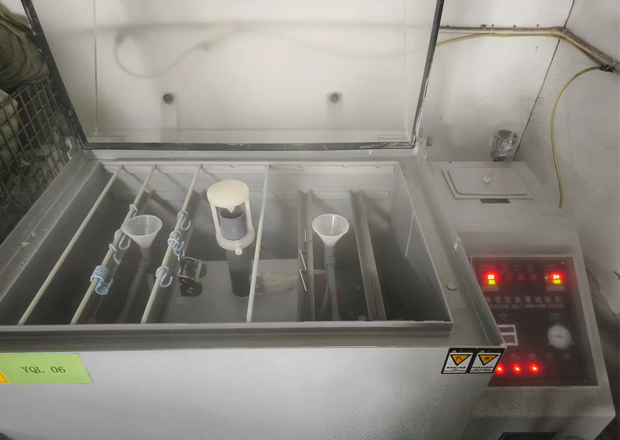

In Sibai, we have salt spray Tester to test the galvanization effect. Some chrome plating, we have to test 720 hours to ensure no rust.