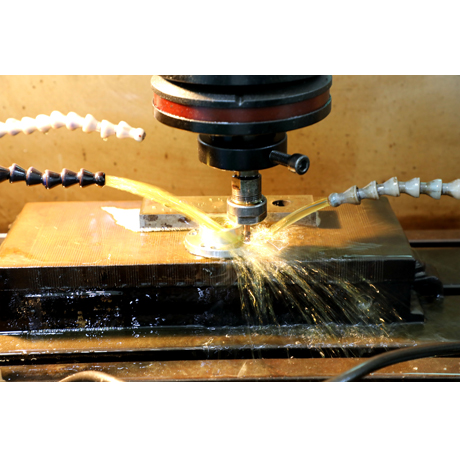

Grinding wheel polishing is the most commonly used polishing method in Sibai in house. For the exposed surface of some workpieces, we adopt grinding wheel polishing to realize mirror polish according to customer needs.

Sibai has two grinding wheel polishing machines, and has specific staff responsible for the polishing work.

The grinding wheel polishing is for mirror polishing on surfaces of copper parts, aluminum parts, and stainless steel parts.

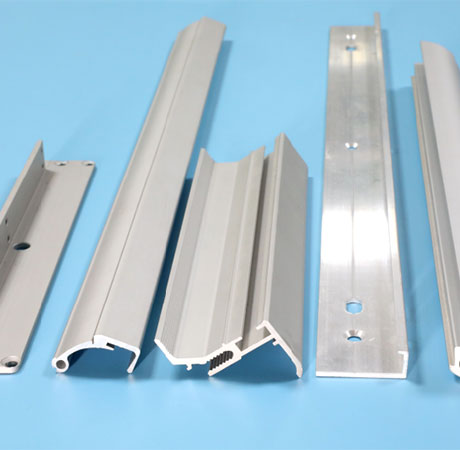

In addition, for some stainless steel, Aluminium, or copper parts, Sibai will also use electrolytic polishing to improve the brightness and finish of the surface.

Electrolytic polishing is chemical polishing, an electrochemical finishing process that removes a thin layer of material from a metal surface, the process leaving a smooth, ultra-clean surface on the metal surface. Electrolytic polishing is particularly suitable for polishing and deburring products with complex geometries.