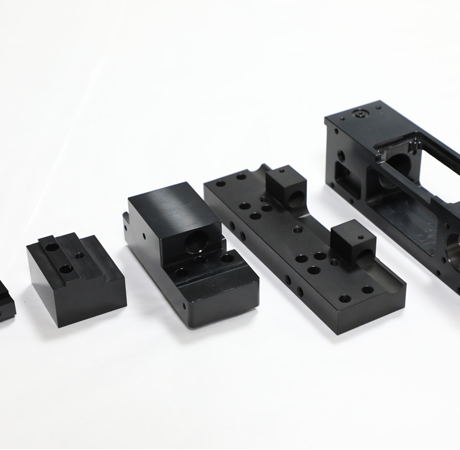

Blackening treatment is a commonly used chemical surface treatment process. It mainly blackens steel and iron parts to improve the anti-rust ability of steel and iron parts, thereby enhancing the corrosion resistance, wear resistance, stability of workpieces and keeping the workpiece beautiful.

The blackening process is widely used, mainly in the fields of automobiles and freighters, and is commonly used process in Sibai.

In order to avoid the phenomenon of oxidative corrosion on the surface of various metal products after long-term contact with air, blackening uses a variety of chemical substances to produce chemical reactions on the metal surface, so that a layer of 0.5-1.5 micron black oxide film is attached to the surface of the workpiece. It improves the anti-rust ability of the workpiece by isolating the air, increases the surface gloss without fading, and makes the workpiece more beautiful. The commonly used blackening methods include traditional alkaline blackening and normal temperature blackening, which are widely used in various fields.