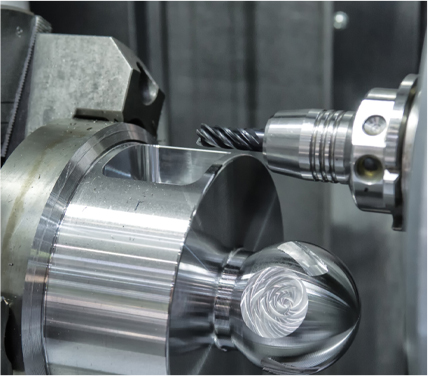

Features of Sibai Machining Capabilities in Plastic Injection Molds

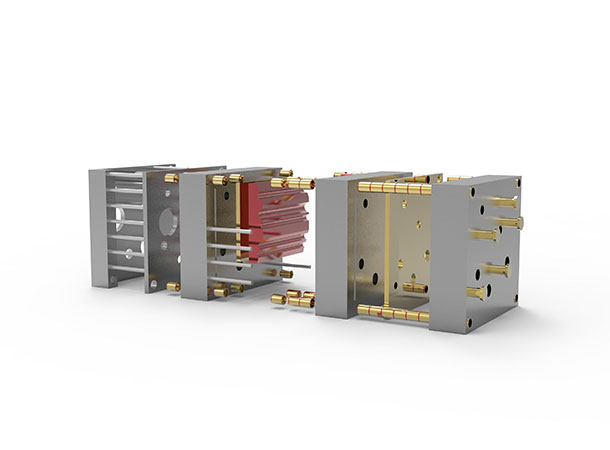

The production of Plastic Injection Molds has both the commonality of the production of general mechanical products and its particularity. Compared with general mechanical manufacturing, Plastic Injection Molds are usually more difficult to manufacture. As a special process equipment, its mold production and process mainly have the following characteristics:

1. High cost of single-piece production

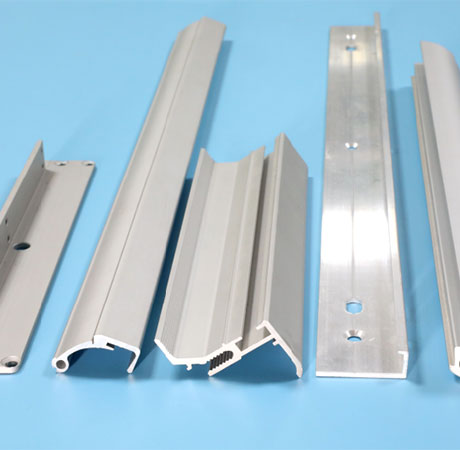

It is difficult to buy Plastic Injection Molds in the electromechanical market. Since each set of molds is customized and processed according to the specifications of specific plastic products. The shape and size of the products are very different, and the geometry of the molds is also very different, so mass production is impossible.

2. Short manufacturing cycle

Due to the Plastic Injection Mold is tailored for a certain product, once the mold test sample is confirmed, the production capacity of mass-produced products is much higher than that of mechanical products, so the manufacturing cycle is short.

3. High technical requirements

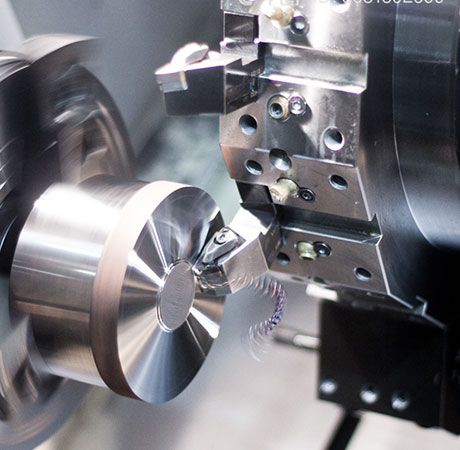

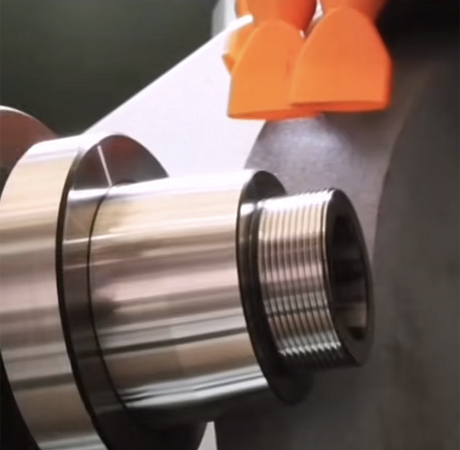

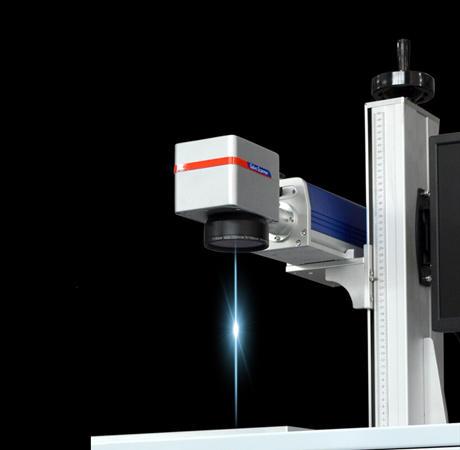

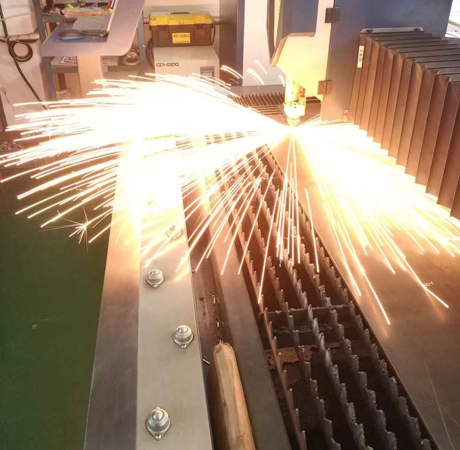

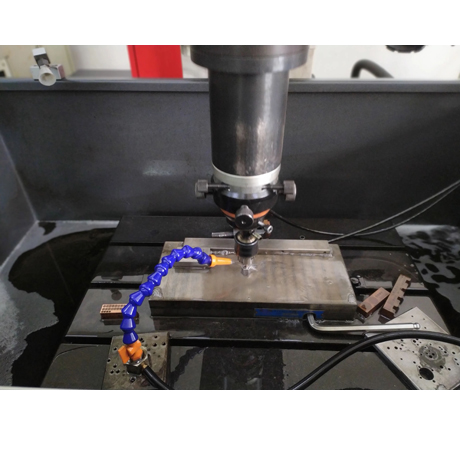

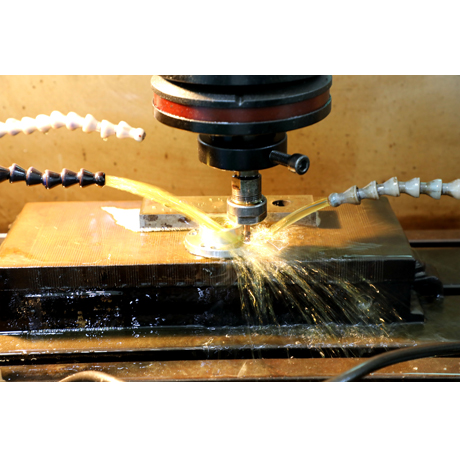

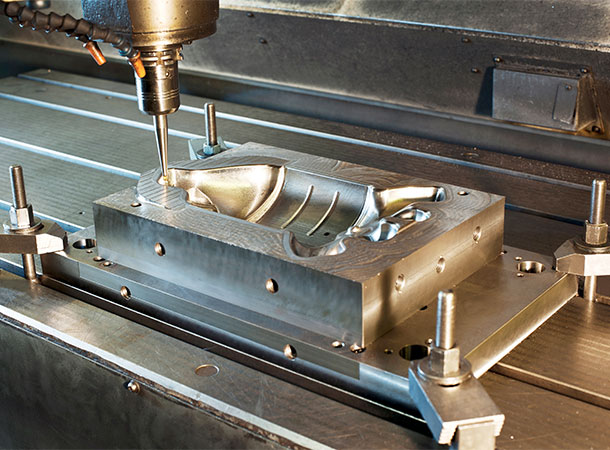

The processing engineering of Plastic Injection Molds concentrates part of the essence of advanced technology in machinery manufacturing and the manual skills of fitter technology, so mold workers are required to have a high technical level to meet the requirements of various process technologies.

In addition, Plastic Injection Molds not only have high requirements for processing accuracy, but also very strict requirements for surface quality. The surface roughness of the processed product is required to be Ra<0.8um.

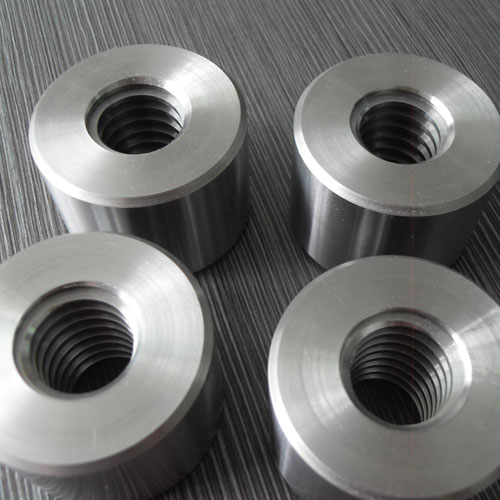

4. High hardness of the material

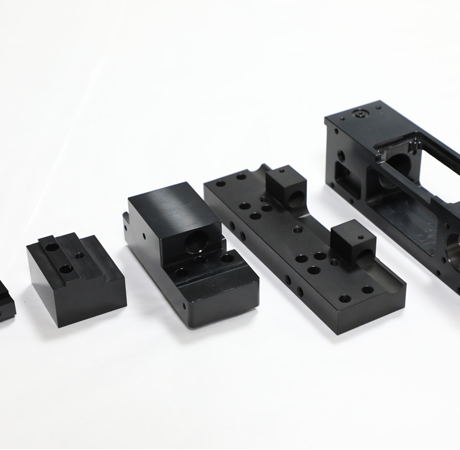

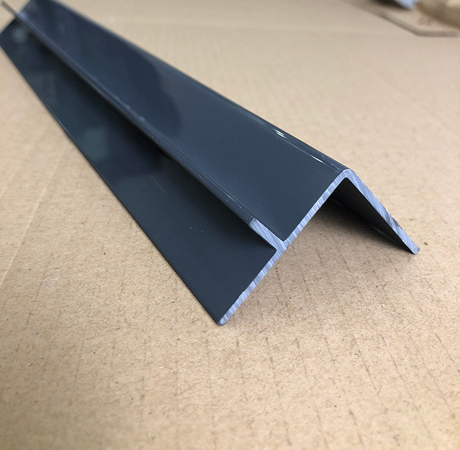

Plastic Injection Molds have high requirements on hardness, and are generally made of hardened alloy tool steel or cemented carbide, which are usually difficult to manufacture by traditional processing methods.

Sibai has made some Plastic Injection Molds for many years, and complex surfaces such as two-dimensional or three-dimensional are welcome to consult or customize.

Welcome to Sibai.

We are looking forward to contact you!

If you have any questions or machining requests, please just leave your message here.