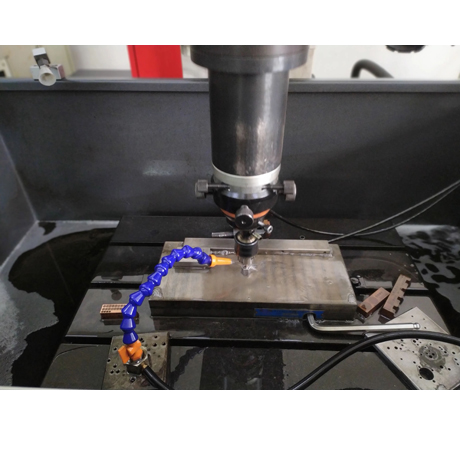

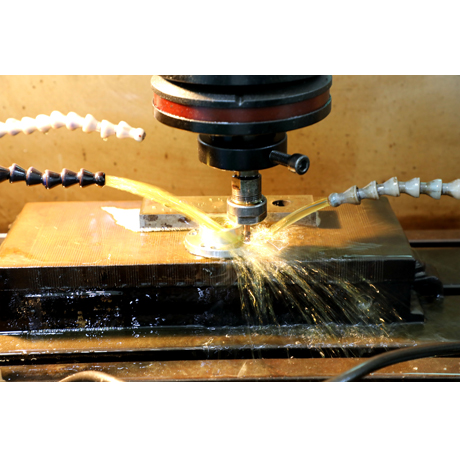

Copper machined parts have become an essential component in the electronics and telecommunications industry. As a leading precision machining manufacturer, Sibai is at the forefront of providing high-quality components for a wide range of applications. In this blog, we will explore the various ways in which copper machined parts are used in electronics and telecommunications.

Copper machined parts in printed circuit boards (PCBs)

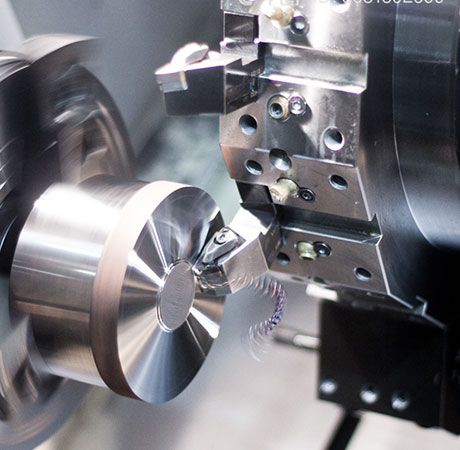

When it comes to manufacturing printed circuit boards (PCBs), copper machined parts play a crucial role. Copper is an excellent conductor of electricity and heat, making it an ideal material for use in PCBs. Copper machined parts are used to create the circuit traces on the PCB, allowing for the seamless flow of electricity between components. With the rise of compact and high-performance electronic devices, the demand for precision-machined copper parts for PCBs has never been higher.

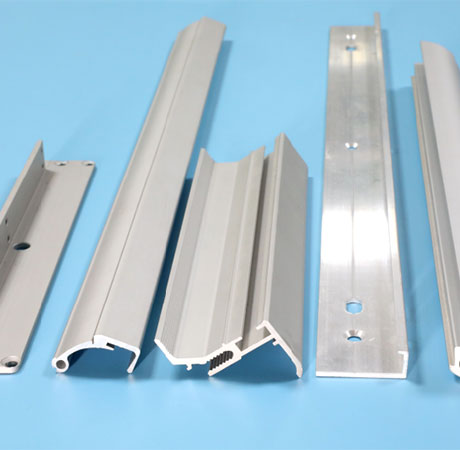

Copper machined parts in antennas

In the telecommunications industry, antennas are used to transmit and receive signals for mobile phones, TVs, radios, and other devices. Copper machined parts are commonly used in the construction of antennas due to their excellent conductivity and corrosion resistance. By using copper machined parts, antenna manufacturers can ensure that their products have a reliable and consistent performance, even in harsh environmental conditions.

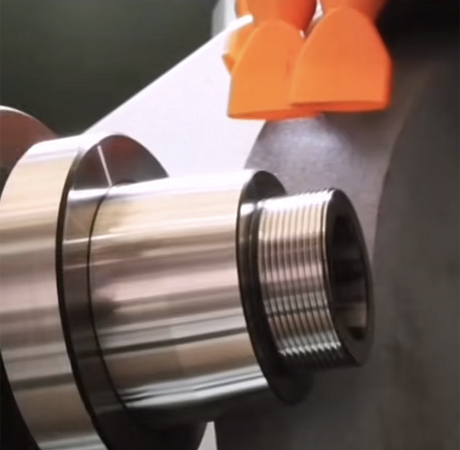

Copper machined parts in connectors and contacts

Connectors and contacts are critical components in electronic devices that enable the transfer of signals between different parts of a circuit. Copper machined parts are often used in the manufacturing of connectors and contacts due to their high conductivity and durability. Whether it's a USB connector on a smartphone or a power socket on a computer, copper machined parts play a vital role in ensuring a reliable connection and efficient signal transmission.

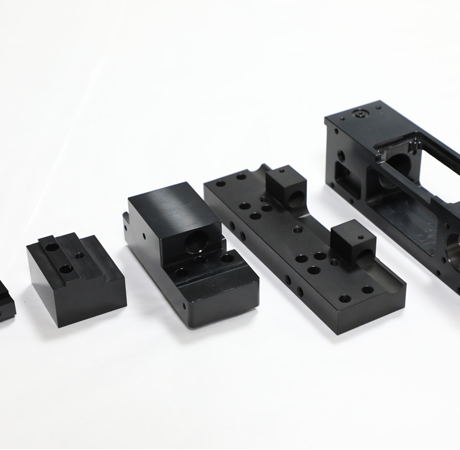

Copper machined parts in heat sinks

As electronic devices become more powerful and compact, managing heat dissipation has become a major challenge for manufacturers. Copper machined parts, such as heat sinks, are used to dissipate heat and keep electronic components within a safe operating temperature range. Copper has a high thermal conductivity, making it an excellent material for heat sinks that can efficiently transfer heat away from sensitive components. By using precision-machined copper parts in heat sinks, manufacturers can improve the reliability and longevity of electronic devices.

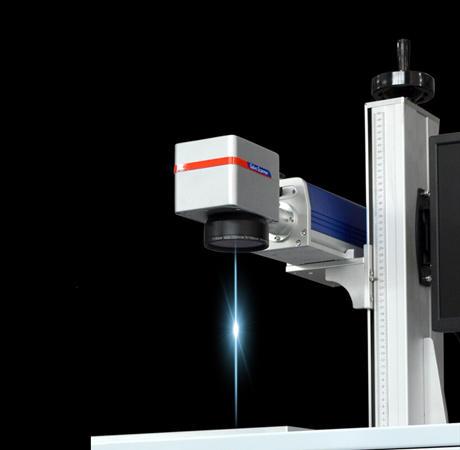

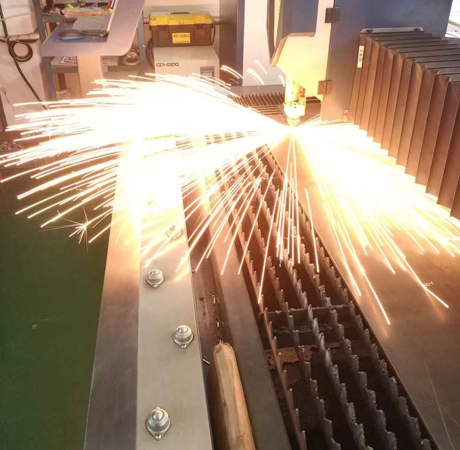

In conclusion, copper machined parts play a crucial role in the electronics and telecommunications industry, enabling the development of advanced and reliable products. Whether it's in PCBs, antennas, connectors, or heat sinks, copper machined parts offer a combination of high conductivity, durability, and thermal properties that are essential for modern electronic devices.

As a trusted manufacturer of copper machined parts, sibai is committed to providing high-quality components that meet the demanding requirements of the industry. If you are looking for reliable and precision-machined copper parts for your electronics and telecommunications applications, look no further than sibai.