In the realm of fluidic precision systems, CNC copper parts are leading the way in ensuring efficient and accurate operation. These intricate components play a crucial role in the functionality and performance of various systems, from healthcare equipment to industrial machinery. As a leading provider of CNC copper parts, sibai is dedicated to delivering top-notch quality and craftsmanship to meet the demands of modern industries.

The Importance of CNC Copper Parts in Fluidic Precision Systems

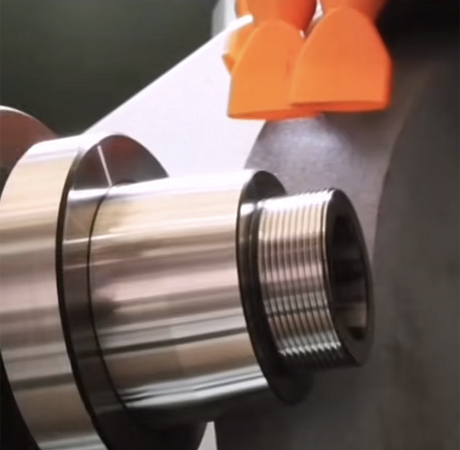

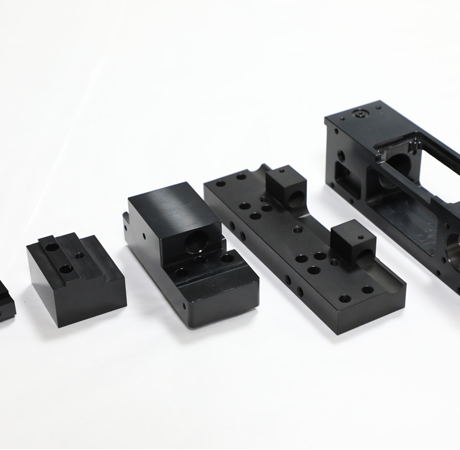

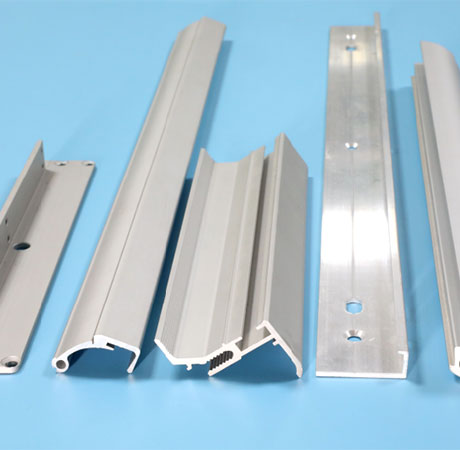

CNC copper parts are essential components in fluidic precision systems due to their ability to withstand corrosion, high temperatures, and high pressure. With their excellent thermal conductivity and electrical conductivity properties, copper parts ensure optimal efficiency and performance of fluidic systems. From valves and fittings to manifolds and connectors, CNC copper parts are a crucial factor in maintaining the integrity and functionality of fluidic systems across various industries.

Advantages of Using CNC Copper Parts in Fluidic Precision Systems

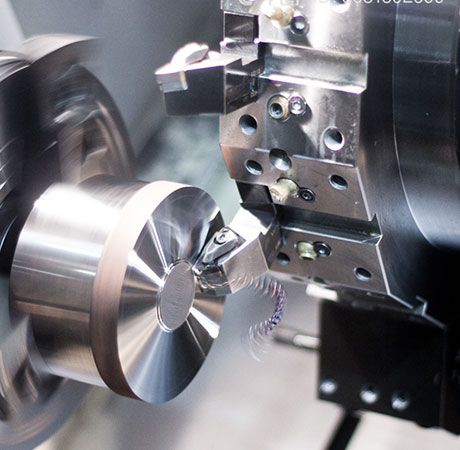

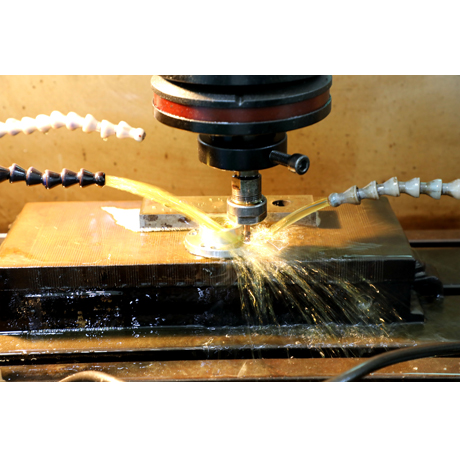

The use of CNC copper parts in fluidic precision systems offers numerous advantages, including superior durability, high precision, and excellent machinability. The unique properties of copper, such as its malleability and ductility, make it an ideal material for producing intricate and complex components with tight tolerances. CNC machining further enhances the precision and consistency of copper parts, ensuring that they meet the exact specifications required for fluidic systems to operate seamlessly.

Sibai - Your Trusted Partner for CNC Copper Parts

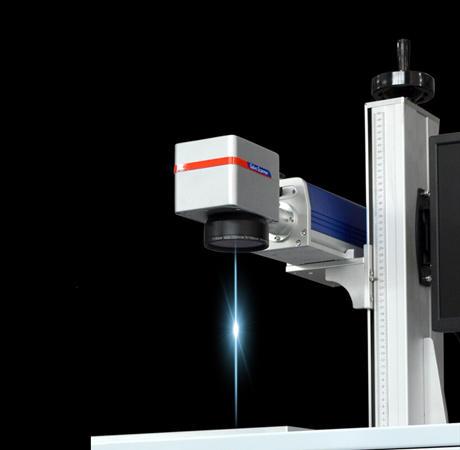

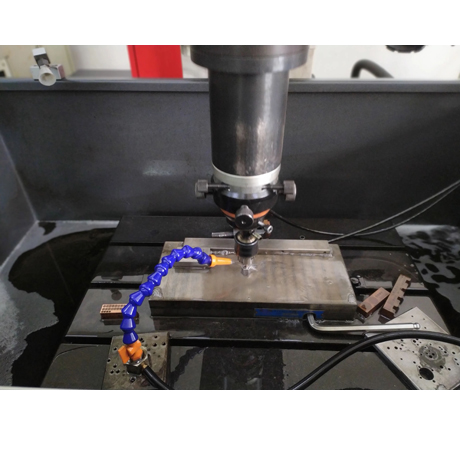

As a reputable precision machining manufacturer, sibai prides itself on delivering high-quality products that meet the stringent requirements of fluidic precision systems. With state-of-the-art machining capabilities and a team of skilled engineers and technicians, sibai ensures that every copper part is meticulously crafted to perfection. From design and prototyping to production and quality control, sibai maintains strict standards to guarantee the reliability and performance of each CNC copper part.

Innovations in CNC Copper Parts for Fluidic Precision Systems

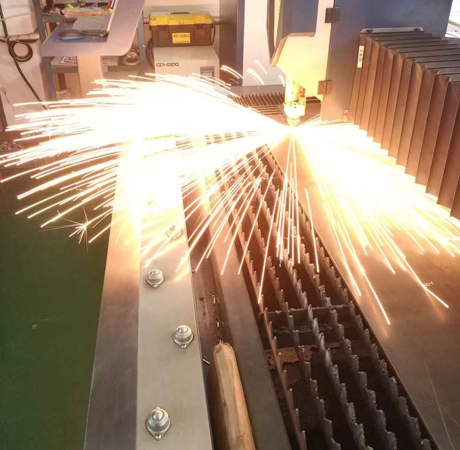

With advancements in technology and manufacturing processes, CNC copper parts continue to evolve and improve, offering enhanced features and capabilities for fluidic precision systems. Sibai stays at the forefront of these innovations, constantly exploring new techniques and materials to push the boundaries of CNC machining. By staying ahead of the curve and adopting cutting-edge technologies, sibai remains a trusted partner for industries seeking top-tier CNC copper parts for their fluidic systems.

In conclusion, CNC copper parts are indispensable components in fluidic precision systems, providing the durability, precision, and reliability required for optimal performance. As a leading manufacturer of CNC copper parts, sibai is committed to delivering superior quality and craftsmanship to meet the diverse needs of modern industries. With a focus on innovation and excellence, sibai continues to lead the way in the evolution of CNC copper parts for fluidic systems, ensuring that they remain at the forefront of technological advancements.