In the world of advanced manufacturing, titanium stands out as a remarkable material known for its exceptional strength, corrosion resistance, and lightweight properties. When coupled with the precision of CNC (Computer Numerical Control) machining, it becomes a game-changer in shaping innovations in aerospace and medical industries. In this article, we'll explore how titanium CNC machining is instrumental in the development of groundbreaking solutions in these two critical sectors.

The Allure of Titanium

Strength and Durability

Titanium's incredible strength-to-weight ratio makes it an ideal choice for industries where structural integrity and weight reduction are paramount. Aerospace and medical applications often require materials that can withstand extreme conditions, and titanium fits the bill perfectly.

Biocompatibility

In the medical field, titanium is favored for its biocompatibility. It doesn't react negatively with the human body, making it an excellent choice for surgical implants and medical devices. This biocompatibility minimizes the risk of complications and allergic reactions.

The Role of CNC Machining in Aerospace

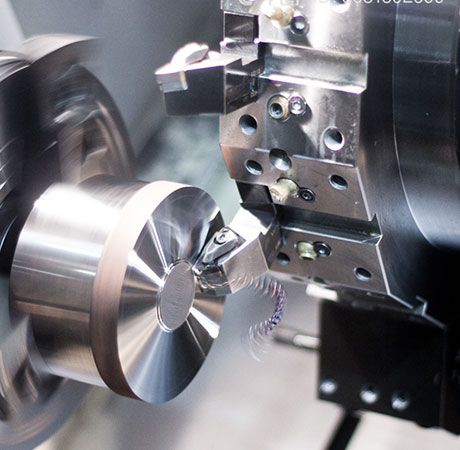

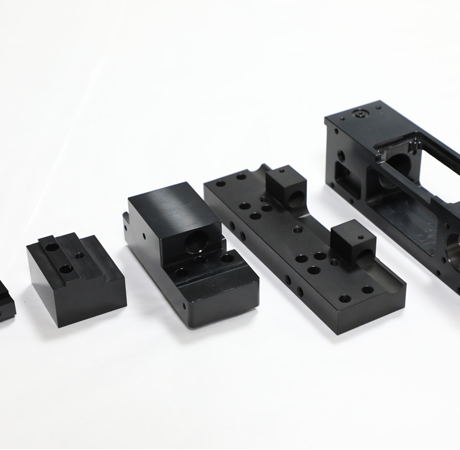

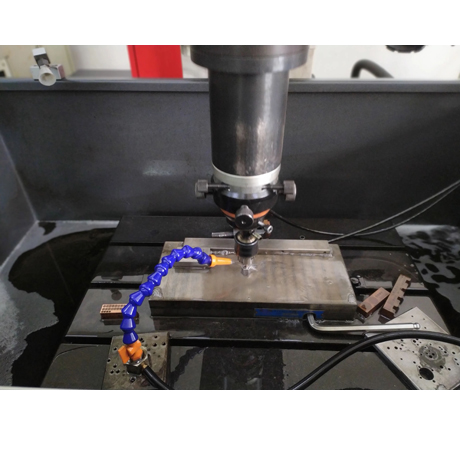

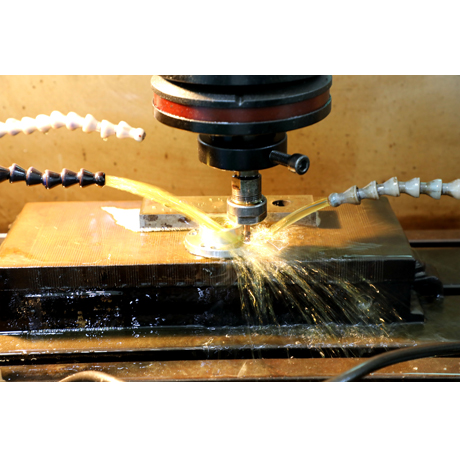

Complex Aerospace Components

Aerospace manufacturers rely on titanium CNC machining to produce complex and critical components for aircraft and spacecraft. These components, such as turbine blades, engine parts, and structural components, demand precision and reliability. CNC machines can shape titanium into intricate forms with micrometer-level accuracy.

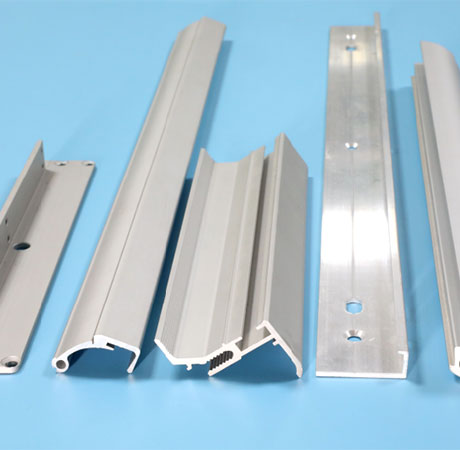

Lightweight Structures

Aerospace engineers strive to reduce the weight of aircraft and spacecraft to enhance fuel efficiency and payload capacity. Titanium's lightweight properties, combined with CNC machining's ability to remove material precisely where needed, contribute to the development of lightweight yet robust structures.

Titanium in the Medical Industry

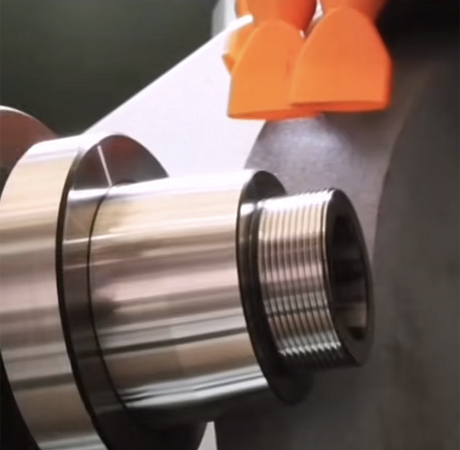

Implants and Prosthetics

Titanium CNC machining plays a crucial role in the production of medical implants and prosthetics. These devices must be manufactured with extreme precision to ensure a perfect fit and functionality within the human body. CNC machining enables the creation of customized implants that meet the unique needs of patients.

Dental Applications

Titanium's biocompatibility extends to dental applications as well. CNC machining is used to create dental implants, crowns, and bridges that offer durability and longevity, improving the quality of life for many patients.

Advancements and Innovations

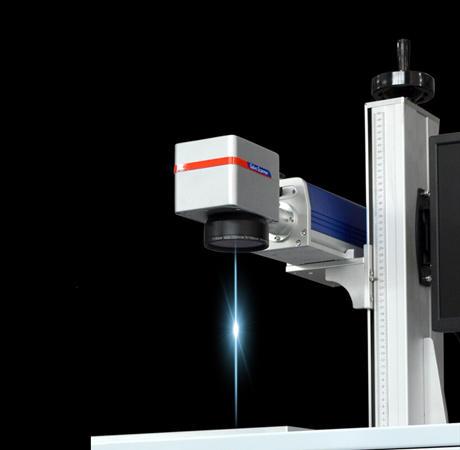

Materials and Techniques

As technology advances, so does the field of titanium CNC machining. Innovations in materials and machining techniques continue to push the boundaries of what's possible. This includes the development of new titanium alloys and improved machining processes, enhancing the material's properties and expanding its applications.

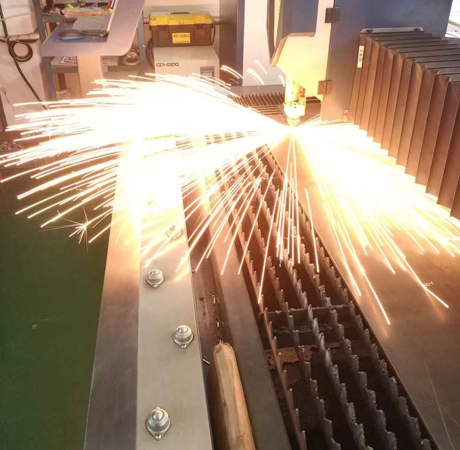

Miniaturization and Integration

In both aerospace and medical fields, there is a growing trend toward miniaturization and integration of components. Titanium CNC machining allows for the production of smaller and more intricate parts, opening up new possibilities for compact and highly efficient devices and systems.

Titanium CNC machining is a driving force behind innovation in aerospace and medical industries. Its ability to shape titanium with precision and reliability makes it indispensable for producing critical components, implants, and devices. As technology continues to evolve, titanium CNC machining will play a pivotal role in shaping the future of these industries, enabling lighter, stronger, and more advanced solutions for the benefit of society. By embracing the potential of titanium and CNC machining, aerospace and medical professionals are shaping a future marked by groundbreaking innovations and improved quality of life.